In the world of industrial manufacturing, every component counts. When even a single piece falters—be it a spacer, slider, or insulating block—it can create a domino effect across the production line, grinding progress to a halt, escalating downtime, and swelling maintenance costs. This is why I keep going back to one of the most adaptable, resilient, and cost-effective materials in my toolbox: the nylon block. Often underestimated, nylon blocks deliver the kind of rugged reliability that industrial systems demand, all while remaining versatile enough to meet customized specifications across different sectors.

Whether you're in medical device production, food and beverage processing, automated machinery, or heavy-duty fabrication, custom nylon blocks are not just a smart material choice—they're a strategic one. With the right design and machining process, nylon blocks can consistently hold tolerances within ±0.005 inches, depending on variables such as tooling sharpness, feed rate, thermal expansion control, and the nylon grade being used. For instance, cast nylon tends to offer slightly more dimensional stability compared to extruded variants due to its lower internal stress. Moreover, factors like toolpath optimization in CNC machining and controlled cooling after fabrication significantly influence the block's final accuracy. This level of fine-tuned tolerance is essential in sectors like medical device manufacturing, where millimeter-level precision can determine a device’s performance or failure. In high-speed food packaging lines, it ensures seamless alignment and uninterrupted product flow—both critical for efficiency and compliance with safety regulations.

The Science Behind Nylon Spacers: Building Blocks of Industrial Robustness

Let’s break it down. Nylon spacers might appear simple at a glance, but their role in mechanical systems is anything but trivial. These small, often unseen components serve a massive function—aligning assemblies, reducing metal-on-metal contact, dampening vibration, and distributing load stress.

When manufactured from high-grade nylon block material, spacers take on enhanced capabilities:

-

Outstanding wear resistance, ensuring long-term durability under constant friction—even in high-cycle environments. Under typical industrial loads, nylon spacers can maintain performance for tens of thousands of cycles without degradation, making them ideal for applications like automated conveyor lines, robotic arms, and press-fit assemblies.

-

Superior chemical resistance, allowing use in environments with oils, solvents, and mild acids where many metals or untreated plastics would corrode or degrade. This quality makes nylon spacers particularly reliable in chemical processing and food equipment washdown zones.

-

Excellent dimensional stability, holding shape under continuous pressure and thermal fluctuation. This quality is essential in precision equipment where thermal cycling or mechanical load changes could otherwise lead to material creep or deformation. Nylon's ability to resist shape distortion means components stay properly aligned over time, reducing the need for recalibration and minimizing premature wear on neighboring parts.

-

Low weight-to-strength ratio, helping reduce stress on dynamic parts without compromising function. In high-speed or high-vibration settings, this translates into less mechanical resistance, smoother motion, and improved energy efficiency.

In production environments—especially those with moving parts or high-cycle operations—I've seen nylon spacers make a significant difference. For instance, one manufacturing partner replaced aluminum spacers in a high-speed conveyor system with nylon. The result? Fewer component replacements, reduced noise, and a 20% improvement in system longevity. Even more impressive was the fact that routine maintenance intervals were extended from every 4 weeks to every 12 weeks, significantly lowering labor costs and improving operational uptime.

Polyamide Blocks: Versatility Meets Industrial Strength

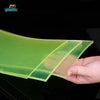

In technical documentation, you may come across the term polyamide blocks—just another way to refer to nylon blocks. But don’t let the name change fool you; the performance is equally impressive. Polyamide is a category of thermoplastic polymers known for their toughness, resilience, and resistance to wear and temperature extremes.

From cleanroom environments to high-heat manufacturing lines, polyamide blocks deliver reliability under pressure. They're commonly used for:

-

Custom bushings that withstand repetitive motion and friction

-

Wear pads in food processing where sanitation is critical

-

Guides and brackets in packaging and bottling systems

One food processor I worked with swapped stainless steel wear strips for FDA-compliant nylon guides. The change dramatically reduced cleaning time, minimized contamination risk, and cut maintenance hours in half. These aren't just savings—they're competitive advantages.

Additionally, nylon blocks are non-conductive and can be used in electrical equipment manufacturing for support brackets and isolation plates, especially where space and safety are at a premium.

Innovations in Industrial Nylon Parts: From Concept to Production

Nylon machining has evolved dramatically over the past decade. What once required multiple fabrication steps can now be completed in a single CNC pass, thanks to advancements in cutting tools and 3D modeling software. Nylon blocks are no longer limited to square-cut pads or simple discs. Today, they can be machined into:

-

Intricate gear components

-

Ergonomic handles

-

Reinforced load-bearing inserts

I recently collaborated with an OEM (original equipment manufacturer) that needed lightweight yet strong supports for a robotic assembly line. Metal was too heavy; other plastics too brittle. Nylon was the sweet spot. After iterating a few prototypes using CAD files and testing the physical stress response, we delivered a machined nylon solution that shaved 15% off the arm’s total weight without sacrificing structural integrity.

With nylon blocks, scalability is a non-issue. Whether you need a one-off prototype for testing or thousands of identical parts, nylon offers consistency and repeatability with cost-effective results.

Tailoring Success: Custom Nylon Components for Optimized Manufacturing

Custom nylon components are where real innovation happens. Standard parts don’t always fit real-world requirements, especially when working in industries that deal with strict regulatory environments, demanding operating cycles, or tight design constraints.

Every successful project I’ve worked on started with a deep discovery process. That means asking:

-

What is the mechanical load and stress cycle of the part?

-

Will it be exposed to chemicals, moisture, or UV?

-

Are there regulatory requirements like FDA, RoHS, or ISO to meet?

Once we have those details, we dial in everything from nylon grade selection (cast vs. extruded, glass-filled vs. virgin) to surface finish and post-machining inspection protocols. For food applications, we’ve designed antimicrobial nylon blocks; for mining operations, we’ve built oversized impact pads that absorb thousands of pounds per square inch.

Ultimately, custom nylon solutions reduce the risk of failure and ensure optimal performance, especially when downtime costs hundreds or thousands of dollars per hour.

High-Performance Nylon: A Game Changer in Modern Manufacturing

Nylon is not a one-size-fits-all material. There’s nylon 6, nylon 66, filled blends with molybdenum disulfide for added lubrication, and even carbon fiber-infused nylon for structural strength. The beauty of nylon lies in its ability to be customized at both the molecular and physical levels.

Here’s how high-performance nylon compares with other industrial materials:

| Material | Strength-to-Weight | Machinability | Cost Efficiency | Shock Resistance |

|---|---|---|---|---|

| Nylon | High | Excellent | High | Excellent |

| PTFE | Moderate | Moderate | Low | Poor |

| Aluminum | High | Good | Medium | Fair |

| UHMW | Moderate | Fair | High | Good |

In medical device manufacturing, nylon is especially valuable. Non-magnetic, sterilizable, and biocompatible, it’s ideal for imaging equipment and precision handling components. In food production, nylon doesn’t just meet the standards—it exceeds them. Unlike metals, it doesn’t rust or leach, and unlike cheaper plastics, it doesn’t crack under stress.

Ready to Customize Your Nylon Block?

Choosing the right nylon block isn’t just about material—it’s about strategy. It's about engineering a solution that aligns with your equipment goals, your compliance requirements, and your production schedule.

If you're in the planning or prototyping phase, I encourage you to explore the nylon plastic materials page for a deeper dive into properties and grades. For engineers who are ready to source materials, our nylon sheets and rods for industrial use page is where you can see product availability in real time.

Need more than raw materials? Check out our custom plastic processing capabilities, where we offer machining, cutting, and fabrication services tailored to your specs.

Have a specific application in mind or want to discuss your project’s technical requirements? Fill out the form on the right or reach out directly via the custom nylon block inquiry page.

Durability. Precision. Customization. That’s not just what nylon blocks offer—it’s what your operation deserves.