Why Custom-Machined Chain Guides Matter in Industrial Operations

In high-performance industrial environments, precision, durability, and efficiency are non-negotiable. Conveyor systems lie at the core of modern production lines—responsible for ensuring that goods, materials, and components move smoothly and reliably from point A to point B. But while the motors, belts, and control systems often receive the spotlight, it is the conveyor chain guides—a relatively small yet crucial component—that significantly impact the entire system’s performance.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 UPE plastic

When these guides are poorly designed, made from low-grade material, or incorrectly matched to the conveyor’s operational parameters, they can cause significant issues. These include chain misalignment, excessive friction, surface wear, and noise pollution, which collectively lead to increased maintenance, downtime, and operational costs.

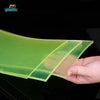

UHMWPE (Ultra High Molecular Weight Polyethylene) has emerged as a material of choice for chain guides thanks to its unique combination of high abrasion resistance, low coefficient of friction, chemical inertness, and long service life. But it’s the custom machining of UHMWPE conveyor chain guides that elevates their benefits—allowing the component to fit seamlessly into the specific layout, pressure, and performance requirements of a conveyor system.

Advantages of Custom UHMWPE Chain Guides Over Standard Plastic Components

While many facilities rely on generic plastic chain guides for simplicity and upfront cost savings, these standard options are often ill-suited for today’s fast-paced, heavy-duty operations. Custom UHMWPE chain guides are precision-engineered to the exact dimensions and shape of the chain, rails, and rollers they serve, dramatically improving the system’s efficiency and reliability.

Here’s how custom UHMWPE guides outperform standard ones:

-

Tailored Fit for Optimal Contact

Unlike standard guides, which come in fixed dimensions, custom-machined UHMWPE guides are designed to match your exact chain profile and conveyor frame. This precise fit ensures smooth contact and minimizes the risk of misalignment or chain derailment. -

Reduced Friction and Energy Consumption

UHMWPE’s naturally low surface friction means that chains can move more freely, with minimal drag. In turn, this reduces the strain on drive motors, contributing to measurable energy savings over time. -

Superior Wear Resistance

When exposed to repeated mechanical motion, UHMWPE outlasts many traditional materials like HDPE or nylon. Its dense molecular structure resists surface abrasion, helping maintain consistent performance even under high-speed, high-load conditions. -

Maintenance Cost Reduction

Standard guides often require frequent replacement or lubrication. Custom UHMWPE guides, on the other hand, offer self-lubricating properties and longer wear cycles—meaning fewer stoppages, lower replacement costs, and reduced labor time. -

Noise Reduction

Custom UHMWPE guides help dampen the metal-on-metal or plastic-on-metal contact that typically occurs in conveyor setups, leading to a quieter and more comfortable working environment.

Boosting Conveyor System Efficiency with Tailored UHMWPE Chain Rails

Chain rails are structural elements that help direct and stabilize conveyor chains along their operational path. The smoother and more precise the rail interface, the more efficient the system becomes.

When off-the-shelf chain rails are installed, they often introduce inconsistencies in chain movement. These inconsistencies can include minor shakes, unexpected vibrations, or slight deflections—all of which might seem negligible at first but can lead to cumulative wear, reduced output, or even system failure.

Custom-machined UHMWPE chain rails eliminate these issues by:

-

Aligning perfectly with the chain’s contour and travel path, ensuring consistent movement even at high speeds.

-

Reducing impact stress caused by sudden directional changes, turns, or heavy loads.

-

Allowing the integration of specialized profiles (T-rails, V-tracks, L-guides, etc.) that fit complex conveyor designs.

For example, in a high-speed bottling plant, replacing steel chain rails with custom-machined UHMWPE rails led to a 20% improvement in throughput by reducing slippage and chain wear while eliminating the need for external lubricants.

Comparing UHMWPE Chain Tracks to Traditional Metal Conveyor Guides

Metal chain guides, typically made from aluminum or stainless steel, have been the default for decades. While these materials are sturdy, they come with trade-offs: higher noise levels, greater weight, corrosion risk, and a higher coefficient of friction.

Custom UHMWPE chain tracks, however, offer a future-ready alternative:

-

Lightweight and Easier to Install

UHMWPE weighs significantly less than steel or aluminum, making installation easier and reducing strain on supporting structures. -

Chemical and Moisture Resistant

Metal guides are prone to rust or corrosion in humid or chemical-rich environments. UHMWPE’s resistance to most chemicals makes it ideal for food processing, pharmaceutical, and marine applications. -

Noise and Vibration Control

In busy facilities, reducing operational noise is critical for safety and communication. UHMWPE’s shock-absorbing properties help control vibration and reduce noise levels dramatically. -

Non-Marking and Non-Abrasive

Metal may scratch or mark the product being conveyed. UHMWPE is gentle on goods, protecting sensitive materials during transport.

In one case study, a meat processing plant in Wisconsin replaced their stainless-steel guides with custom UHMWPE tracks. The result: a 50% reduction in maintenance labor, fewer product scuffs, and a drop in system-related injuries due to reduced noise and slip risks.

How Custom UHMWPE Chain Supports Reduce Operational Costs

Chain supports are the backbone of a conveyor system’s stability. When they’re not designed to accommodate specific loads, temperatures, or chain dimensions, operational costs start piling up.

Custom UHMWPE chain supports offer the following benefits:

-

Extended Lifespan of Components

By evenly distributing pressure and reducing stress on sprockets and bearings, UHMWPE supports help extend the service life of the entire conveyor assembly. -

Reduction in Downtime

With fewer breakdowns and a lower risk of chain derailment, production can continue with minimal interruption. -

Lower Lubrication and Maintenance Needs

UHMWPE’s self-lubricating nature significantly reduces friction, making it easier to maintain and reducing the need for costly lubricants.

Case Story: Custom UHMWPE Support in a Glass Bottle Packaging Facility

A European beverage manufacturer struggled with bottlenecks caused by broken chain supports on a high-volume packaging line. The original supports—made from generic plastic—were cracking under load and deforming from heat. After switching to custom-machined UHMWPE supports, the facility saw:

-

A 3x increase in support lifespan

-

A 90% drop in lubrication requirements

-

40% faster throughput on peak production days

This transformation helped the company avoid a costly system overhaul, instead optimizing the existing system with smarter, more robust components.

Industry Applications of UHMWPE Conveyor Chain Guides

Food & Beverage

In this hygiene-critical sector, UHMWPE’s FDA compliance, chemical resistance, and ease of cleaning make it the go-to material. It's widely used in meat processing lines, dairy conveyor systems, and bottle filling stations.

Automotive & Logistics

For high-load, high-speed chains moving metal parts or pallets, UHMWPE guides reduce noise and vibration. Their resilience helps withstand shocks and impacts from dynamic loads.

Pharmaceutical & Medical

Environments requiring low contamination and precision benefit from UHMWPE’s non-toxic, non-absorbent surface. It’s often found in sterile conveyor setups transporting packaging materials or diagnostic instruments.

E-commerce Fulfillment & Warehousing

Custom guides improve the routing of belt and chain-driven systems for high-volume picking, sorting, and packaging operations. Their ability to run without lubrication reduces mess and improves cleanliness in climate-controlled spaces.

A Long-Term Investment in Performance and Savings

Investing in custom-machined UHMWPE conveyor chain guides is more than an upgrade—it's a long-term strategy for achieving better performance, increased uptime, and reduced total cost of ownership. Their adaptability, durability, and ease of maintenance make them a smart fit for virtually every conveyor-intensive industry.

By working with a trusted machining partner, you can ensure your guides are engineered to meet the exact specifications of your system—resulting in better performance today and fewer breakdowns tomorrow.

✅ Ready to Improve Your Conveyor System?

-

🔧 Explore Custom UHMWPE Chain Guides – Discover tailored solutions for your conveyor system.

-

🛠 Shop UHMWPE Conveyor Components – High-performance parts in stock.

-

⚙️ View Our Manufacturing Capabilities – Learn how we custom machine UHMWPE to spec.

-

📩 Request a Custom Quote for UHMWPE Machining – Let’s build a guide that fits your system perfectly.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 UPE plastic

Transform your chain guide strategy today—engineered for reliability, designed for results.