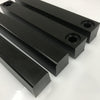

Have you ever wondered what kind of plastic can handle high temperatures, heavy loads, and corrosive chemicals? Well, there is one material that can do all that and more: black POM plastic sheet. POM stands for polyoxymethylene or acetal, and it’s a type of engineering plastic that has amazing mechanical properties. It’s strong, stiff, durable, and resistant to many chemicals. And it’s not just plain white like most plastics. It’s black, which gives it a sleek look and protects it from UV rays. It can even touch food without any problems . In this article, we will show you some of the cool things that black POM plastic sheet can do in different industries, such as automotive, electrical and medical, and how it can make these products better, safer and more reliable.

Automotive Industry

The automotive industry is one of the major consumers of black POM plastic sheet. This material is suitable for making various components that are exposed to high stress, temperature and moisture, such as gears, bearings, valves, plugs and connectors. Black POM plastic sheet can provide the following benefits for automotive applications:

- High mechanical strength and toughness: Black POM plastic sheet can withstand high loads and impacts without breaking or deforming. It can also resist fatigue and creep under repeated stress cycles.

- Low friction and wear: Black POM plastic sheet has a low coefficient of friction and a high resistance to abrasion. It can reduce friction losses and noise in moving parts, and extend the service life of the components.

- Good chemical resistance: Black POM plastic sheet can resist dilute acids, alkalis, fuels, oils and solvents. It can prevent corrosion and degradation caused by these chemicals.

- Improved UV protection: Black POM plastic sheet has a better UV resistance than natural POM plastic sheet due to its black colouring. It can prevent fading and cracking caused by sunlight exposure.

Some examples of automotive products that use black POM plastic sheet are:

- Gear wheels: Black POM plastic sheet can make gear wheels that have high strength, low friction and good dimensional accuracy. These gear wheels can transmit power efficiently and smoothly in various transmission systems.

- Friction bearings: Black POM plastic sheet can make friction bearings that have high load capacity, low friction and good wear resistance. These friction bearings can support rotating shafts and reduce vibration and noise in various machines.

- Valve seats: Black POM plastic sheet can make valve seats that have high rigidity, low friction and good chemical resistance. These valve seats can seal the valves tightly and prevent leakage of fluids or gases in various engines.

- Plugs: Black POM plastic sheet can make plugs that have high strength, good electrical insulation and good chemical resistance. These plugs can connect wires and cables securely and prevent short circuits or corrosion in various electrical systems.

Electrical Industry

The electrical industry is another major consumer of black POM plastic sheet. This material is suitable for making various electrical devices and components that require high insulation, reliability and durability, such as insulators, switches, connectors and housings. Black POM plastic sheet can provide the following benefits for electrical applications:

- High electrical insulation: Black POM plastic sheet has a high dielectric strength and a low dielectric constant. It can prevent electric shocks, sparks or arcs in high voltage or high frequency environments.

- High thermal stability: Black POM plastic sheet has a high melting point and a low thermal expansion coefficient. It can maintain its shape and properties under high temperature or rapid temperature changes.

- Easy to machine and polish: Black POM plastic sheet has a smooth surface and a uniform structure. It can be easily cut, drilled, milled or polished to achieve precise dimensions and shapes.

- Easily welded: Black POM plastic sheet can be easily welded by using heat or ultrasonic methods. It can form strong bonds with other plastics or metals without using adhesives.

Some examples of electrical products that use black POM plastic sheet are:

- Insulators: Black POM plastic sheet can make insulators that have high electrical insulation, high thermal stability and good mechanical strength. These insulators can protect wires, cables or other conductors from electric currents or heat sources in various electrical systems.

- Switches: Black POM plastic sheet can make switches that have low friction, good wear resistance and good electrical insulation. These switches can control the flow of electricity or signals in various circuits or devices.

- Connectors: Black POM plastic sheet can make connectors that have high strength, good electrical insulation and good chemical resistance. These connectors can join wires or cables securely and prevent loose connections or corrosion in various electrical systems.

- Housings: Black POM plastic sheet can make housings that have high rigidity, good thermal stability and good chemical resistance. These housings can enclose electrical components or devices safely and prevent damage from external factors.

Medical Industry

The medical industry is also a major consumer of black POM plastic sheet. This material is suitable for making various medical devices and facilities that require high quality, hygiene and biocompatibility, such as surgical instruments, artificial joints, infusion pumps and sterilization trays. Black POM plastic sheet can provide the following benefits for medical applications:

- High quality: Black POM plastic sheet has a high purity and a low moisture absorption. It can prevent contamination or degradation caused by impurities or moisture.

- High hygiene: Black POM plastic sheet has a smooth surface and a low porosity. It can prevent bacteria or dirt from adhering or penetrating into the material.

- High biocompatibility: Black POM plastic sheet has a low toxicity and a low allergenicity. It can prevent adverse reactions or infections caused by contact with human tissues or fluids.

Some examples of medical products that use black POM plastic sheet are:

- Surgical instruments: Black POM plastic sheet can make surgical instruments that have high strength, low friction and high hygiene. These surgical instruments can perform various operations smoothly and safely without causing damage or infection to the patients.

- Artificial joints: Black POM plastic sheet can make artificial joints that have high rigidity, low friction and high biocompatibility. These artificial joints can replace damaged or diseased joints in the human body without causing pain or rejection.

- Infusion pumps: Black POM plastic sheet can make infusion pumps that have high precision, low friction and high hygiene. These infusion pumps can deliver fluids or drugs into the patients’ bodies accurately and smoothly without causing leakage or contamination.

- Sterilization trays: Black POM plastic sheet can make sterilization trays that have high thermal stability, good chemical resistance and high hygiene. These sterilization trays can hold medical instruments or devices securely and prevent damage from heat or chemicals during sterilization processes.

Conclusion

If you are looking for a high-performance engineering plastic that can meet your diverse needs, you might want to consider black POM plastic sheet. This material is widely used in various industries because of its excellent properties, such as high strength, low friction, good wear resistance, and easy machinability. Whether you need it for gears, bearings, rollers, or other components, black POM plastic sheet can deliver reliable and durable results. To get the best quality and service, you can trust www.beeplastic.com, a professional custom plastics manufacturer with over 20 years of experience. They can produce various engineering plastics products according to your specifications and requirements. Ordering from them is simple and convenient. Just visit their website, fill out the online form, and submit your inquiry. They will get back to you with a quote and a delivery time as soon as possible.