You will not be allowed to compare more than 4 products at a time

View compareCustom Plastic Solutions

Discover the properties and versatile applications of our custom plastic.

Get a Quote

High-Quality FR-4, G10 Epoxy Glass Fiber

High-Performance FR-4/G10 Epoxy Glass Fiber Sheets & Rods

Your Trusted Partner for Advanced Plastic Solutions

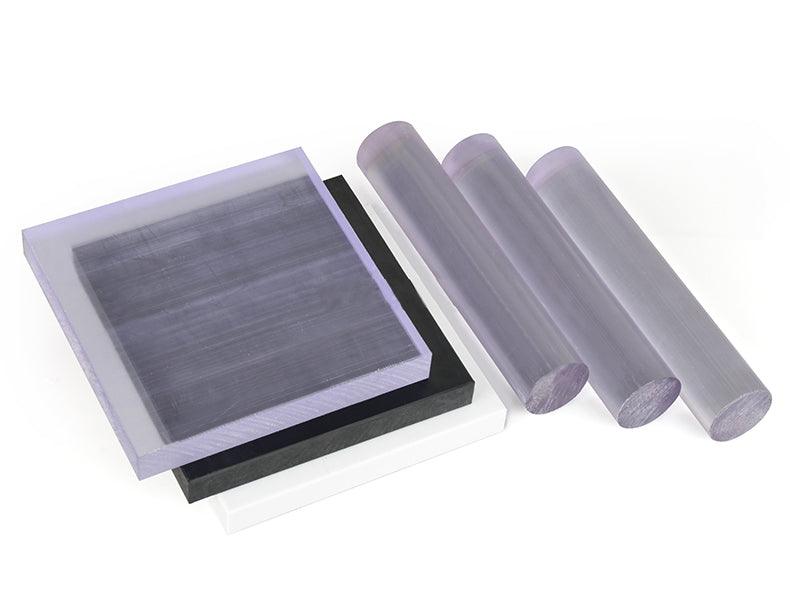

BeePlastic proudly offers FR-4/G10 epoxy glass fiber sheets and rods, engineered to meet the toughest industrial and electronic demands. Crafted from high-strength woven glass fiber cloth and epoxy resin, these materials are renowned for their exceptional mechanical performance, electrical insulation properties, and flame retardancy (FR-4).

Our products serve industries such as electronics, aerospace, marine, automotive, and industrial machinery. Available in water green and black finishes, these sheets and rods cater to applications requiring high precision, durability, and safety.

Whether you are manufacturing printed circuit boards (PCBs), building structural components, or designing custom parts for demanding environments, our FR-4/G10 solutions deliver unmatched performance.

What is FR-4/G10?

What is FR-4/G10?

FR-4 and G10 are glass epoxy laminates that have become the gold standard in industrial and electronic applications. FR-4 incorporates flame-retardant properties, making it ideal for environments where safety is critical, while G10 is a versatile alternative for applications that do not require flame resistance.

Both materials are thermosetting composites, offering excellent dimensional stability and resistance to moisture, heat, and chemicals. This makes them indispensable for creating components that must perform under high stress, whether mechanical, thermal, or electrical.

Why Choose FR-4/G10 from BeePlastic?

- High Strength and Durability: These materials can withstand high mechanical loads and offer superior resistance to wear and tear.

- Electrical Insulation: With a high dielectric strength, FR-4 and G10 protect sensitive components from electrical failures.

- Moisture Resistance: Low water absorption ensures reliability in humid or wet environments.

- Customization Options: BeePlastic offers custom machining and fabrication services to meet specific application needs.

Material Features & Benefits

1. Superior Mechanical Properties

FR-4/G10 materials exhibit high tensile, compressive, and flexural strength, making them suitable for heavy-duty applications. Their robustness ensures long-term reliability, reducing maintenance costs and extending product life.

2. Outstanding Electrical Insulation

Designed for electronic components, these laminates prevent electrical leakage and maintain operational safety, even under high voltages. This is crucial for manufacturing PCBs, switches, and transformer insulation.

3. Thermal Resistance

FR-4 materials can endure continuous operating temperatures up to 130°C while maintaining their physical and electrical properties. This makes them suitable for high-temperature environments such as aerospace systems and industrial machinery.

4. Flame Retardancy

FR-4’s UL94 V-0 certification ensures flame retardancy, providing an additional layer of safety in critical environments, such as marine equipment and fire-sensitive manufacturing setups.

5. Dimensional Stability

These laminates maintain their shape and structural integrity even when subjected to mechanical stress or thermal cycling. Their reliability in demanding conditions makes them a favorite in precision manufacturing.

Specifications

FR-4/G10 Sheets

- Thickness Options: 0.01" to 4.00" (0.25 mm to 100 mm).

-

Standard Sizes:

- 36" x 48" (914 mm x 1219 mm).

- 48" x 96" (1219 mm x 2438 mm).

- Custom dimensions available upon request.

- Colors: Water Green, Black.

FR-4/G10 Rods

- Diameter Range: 0.25" to 4.00" (6.35 mm to 100 mm).

-

Lengths:

- Standard lengths: 36" (914 mm) and 48" (1219 mm).

- Custom lengths available upon request.

- Colors: Water Green, Black.

Applications Across Industries

Electronics

Electronics

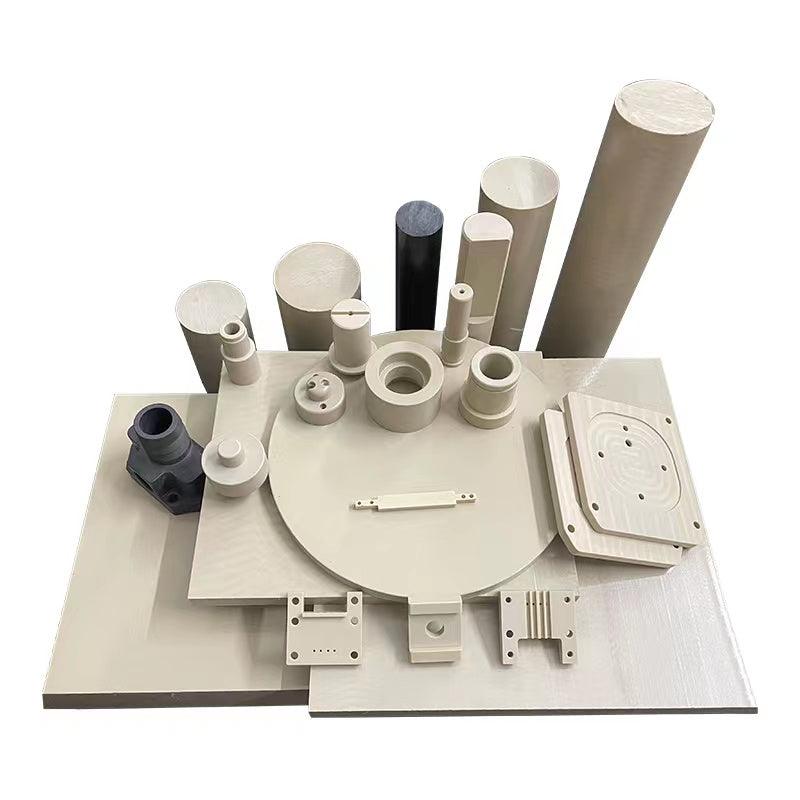

FR-4/G10 sheets and rods are essential in printed circuit boards, providing a stable, non-conductive substrate for electrical components. They are also widely used in insulators, relays, and switchgear, ensuring safe and reliable electrical performance.

Aerospace

In aerospace applications, FR-4/G10 laminates contribute to lightweight and durable components such as structural mounts, housings, and brackets. Their resistance to heat, flame, and mechanical stress ensures performance in the most demanding conditions.

Marine

With excellent moisture resistance and flame retardancy, these materials are perfect for offshore and marine environments. Applications include pump housings, valve seats, and moisture-proof insulators.

Automotive

Automotive manufacturers rely on FR-4/G10 materials for high-performance applications such as gear bushings, motor insulation, and under-the-hood components that require a combination of mechanical strength and electrical insulation.

Industrial Machinery

In heavy-duty industrial applications, FR-4/G10 materials excel in the manufacture of gears, bearings, bushings, and structural supports. Their ability to withstand high mechanical and thermal stress ensures reliable operation under challenging conditions.

Explore More Materials

Looking for other advanced plastic materials? We offer a comprehensive range of options to meet your needs. Click on any material below to learn more:

| Material Name | Full Name | Applications | Key Properties |

|---|---|---|---|

| ABS | Acrylonitrile Butadiene Styrene | Automotive, Electronics, Medical Devices | Durable, Impact Resistant, Easy to Machine |

| HDPE | High-Density Polyethylene | Piping, Bottles | High Strength-to-Density Ratio |

| UHMW-PE | Ultra-High-Molecular-Weight Polyethylene | Conveyor Belts, Bearings | Extremely High Wear Resistance |

| Nylon | Polyamide | Gears, Bearings | High Mechanical Strength, Good Wear Resistance |

| PI | Polyimide | Flexible Printed Circuits | High Heat Resistance |

| PEI | Polyetherimide | Medical Devices, Aircraft Interiors | High Strength, Flame Resistance |

| PEEK | Polyether Ether Ketone | Aerospace Parts, Medical Implants | High Temperature and Chemical Resistance |

| PP | Polypropylene | Packaging, Textiles | Chemical Resistance, Elasticity |

| PET | Polyethylene Terephthalate | Beverage Bottles, Food Containers | High Strength, Thermoformability |

| PAI | Polyamide-imide | Automotive Components, Electrical Insulation | High Strength, Thermal Stability |

| Acrylic | Polymethyl Methacrylate (PMMA) | Displays, Lenses | Transparency, Weather Resistance |

| PTFE | Polytetrafluoroethylene | Non-Stick Coatings, Gaskets | Low Friction, Chemical Resistance |

| POM | Polyoxymethylene (Acetal) | Precision Parts, Gears | High Stiffness, Low Friction |

| PC | Polycarbonate | Safety Glasses, CDs | High Impact Resistance, Transparency |

| PPS | Polyphenylene Sulfide | Automotive Parts, Electronics | High Temperature Resistance, Chemical Stability |

| PVC | Polyvinyl Chloride | Pipes, Cable Insulation | Durability, Chemical Resistance |

| PVDF | Polyvinylidene Fluoride | Chemical Processing Equipment | High Chemical Resistance, Purity |

| PU | Polyurethane | Foam Seating, Insulation Panels | Flexibility, Durability |

| FR-4/G10 | Flame Retardant Glass-Reinforced Epoxy Laminate | Printed Circuit Boards | Flame Resistance, Mechanical Strength |

| Bakelite | Phenol Formaldehyde Resin | Electrical Insulators, Radio Casings | High Mechanical Strength, Heat Resistance |

Learn More

Fully Customizable to Your Specifications

At BeePlastic, we offer precision cutting and machining to produce sheets and rods that perfectly fit your project's specific dimensions and requirements.

Tailored Solutions Across Industries

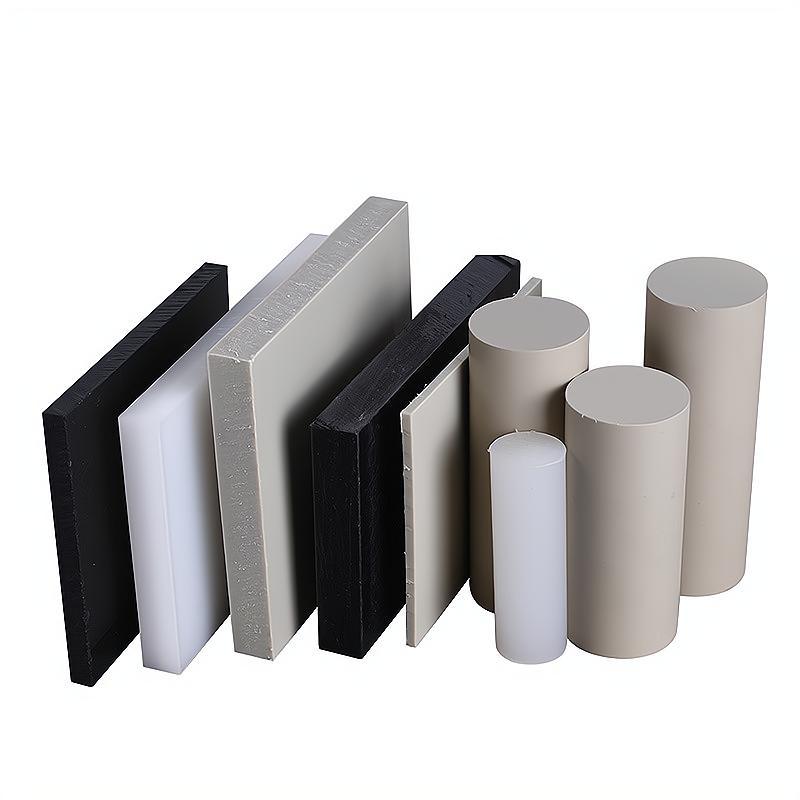

Explore Our Full Range of Plastic Materials

Discover the versatility and quality of our extensive plastic materials portfolio. From standard sheets to highly specialized rods, each product is designed to meet the diverse needs of industries including aerospace, automotive, and healthcare. Browse our collection to find the perfect material suited to your project requirements.

Browse Our Material Catalog