You will not be allowed to compare more than 4 products at a time

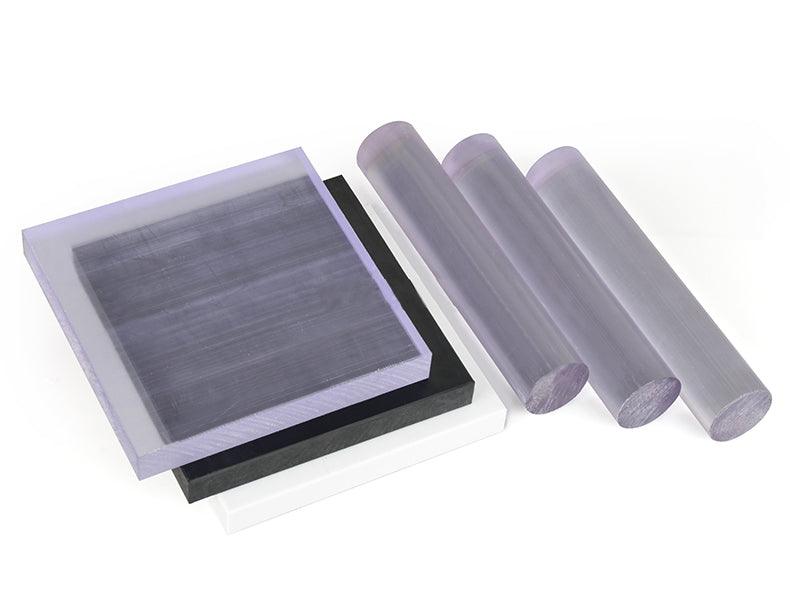

View compareCustom Plastic Solutions

Discover the properties and versatile applications of our custom plastic.

Get a Quote

Custom UHMW-PE

Discover the Superiority of UHMW PE with Bee Plastic

Introduction to UHMW PE

Ultra-High Molecular Weight Polyethylene (UHMW PE) stands out in the world of polymers. Renowned for its exceptional strength and versatility, UHMW PE is a game-changer in various industries.

Unveiling UHMW PE: A Polymer of Many Names

Ultra-High Molecular Weight Polyethylene, commonly known as UHMW PE, is a marvel in the world of advanced materials. In Europe and America, this versatile polymer is also recognized under specialized brand names like LUBMER™, HI-ZEX MILLION™, and MIPELON™. These variations embody the same core qualities of UHMW PE but are tailored for specific industrial applications.

The Essence of UHMW PE

At its core, UHMW PE is celebrated for its remarkable strength and durability. This thermoplastic boasts an impressive molecular weight, which translates into extraordinary resistance to wear and abrasion, making it a preferred choice in demanding environments.

Beyond the Name - A Polymer for All Seasons

Whether it's known as LUBMER™ in a European factory or HI-ZEX MILLION™ in an American tech lab, UHMW PE's attributes remain constant. Its low friction coefficient and high impact resistance make it an ideal material for a myriad of applications, ranging from medical devices to aerospace components.

A Comparison with Alternatives

In the global market, UHMW PE stands out as a more cost-effective and versatile alternative to materials like PTFE. Its ability to perform under extreme conditions without compromising on quality or efficiency makes it a go-to material for innovators and industry leaders alike.

Meeting Industry Standards

UHMW PE, in all its forms, meets stringent industry standards. Products like MIPELON™ are designed to offer high flexibility and impact strength, even at low temperatures, aligning with the rigorous demands of various sectors.

Embracing Sustainability

In today's eco-conscious world, UHMW PE's sustainability factor is a significant advantage. Brands like LUBMER™ highlight the material's ability to be recycled, reducing its environmental footprint and appealing to a market that values green solutions.

Why Choose UHMW PE?

UHMW PE is not just another plastic. Its unique properties, such as high wear resistance, low friction, and outstanding impact strength, set it apart. When compared to materials like HDPE, UHMW PE offers unparalleled performance.

Superior to Traditional Materials

UHMW PE stands out as a more cost-effective and versatile alternative to traditional materials like PTFE. Its unique blend of properties, including high wear resistance and excellent sliding properties, make it a preferred choice in a range of applications, from industrial parts to surface coatings.

A Sustainable Choice

In an era where sustainability is paramount, UHMW PE, offers a significant advantage. These materials can be recycled, reducing their environmental impact and aligning with global sustainability goals.

Meeting Industry-Specific Needs

Whether it's the highly abrasion-resistant L5000 or the flexible and impact-resistant MIPELON™, these UHMW PE formulations meet the specific demands of various industries, from automotive to medical.

A Solution for Every Challenge

UHMW PE's adaptability is evident in its ability to replace more costly materials in applications that do not require extreme heat resistance. This adaptability extends to its various formulations, each designed to offer optimal performance in specific conditions.

Key Properties and Benefits

- High Wear Resistance: UHMW PE endures where others fail, especially in abrasive environments.

- Low Friction: Its slick surface reduces wear and energy consumption in machinery.

- Impact Strength: Capable of absorbing high impacts without damage.

- Chemical Resistance: Resists corrosion from harsh chemicals.

- Temperature Resilience: Performs exceptionally in extreme temperatures.

High Durability and Wear Resistance

Ultra-High Molecular Weight Polyethylene (UHMW PE) is renowned for its exceptional durability and wear resistance. This makes it an ideal material for applications where high levels of friction and wear are expected. Its resistance to abrasion is significantly higher than many metals, including carbon steel, which is why it's frequently used in high-wear environments.

Low Friction Coefficient

One of the standout properties of UHMW PE is its very low coefficient of friction. This characteristic is comparable to that of PTFE (Teflon), but UHMW PE offers superior abrasion resistance. This low friction quality makes it an excellent choice for applications where sliding motion of parts is involved, such as in conveyor systems or gear parts.

Chemical Resistance

UHMW PE is highly resistant to a wide range of chemicals, including concentrated acids and alkalis, as well as numerous organic solvents. This chemical resistance makes it suitable for use in environments where exposure to harsh chemicals is a concern, such as in chemical processing plants or in the lining of tanks and pipes.

Impact Strength

UHMW PE possesses the highest impact strength of any thermoplastic currently made. This property is particularly valuable in applications where the material is subject to sudden, high-impact forces, such as in protective gear or industrial machinery components.

Moisture Resistance and Non-Toxicity

This material is odorless, tasteless, and non-toxic, and it exhibits extremely low moisture absorption. These properties make UHMW PE suitable for use in food processing industries and medical applications where hygiene and safety are critical.

Temperature Resistance

While UHMW PE performs excellently in a range of temperatures, it is important to note that it becomes brittle at temperatures below −150°C and should not be used at temperatures exceeding 80 to 100°C for extended periods. This temperature range covers most typical industrial and commercial applications.

UV Resistance and Color Stability

UHMW PE is resistant to UV radiation, which helps in maintaining its properties and color when used in outdoor applications. This UV resistance is beneficial for products that are exposed to sunlight for prolonged periods, such as outdoor furniture or marine applications.

Versatility in Applications

The unique combination of properties makes UHMW PE versatile for a wide range of applications. It's used in everything from medical devices and food processing equipment to heavy-duty industrial machinery and protective gear. Its ability to be molded into various shapes and forms further enhances its applicability across different industries.

Environmental Impact and Recyclability

UHMW PE is an environmentally friendly material. It is recyclable, which reduces waste and promotes sustainability in manufacturing processes. This aspect is increasingly important in today's environmentally conscious market, where both manufacturers and consumers are looking for greener alternatives.

Cost-Effectiveness

Despite its high performance and durability, UHMW PE is a cost-effective material. Its long lifespan and low maintenance requirements make it a financially viable option for many industrial applications, providing long-term savings on replacements and repairs.

In conclusion, the key properties and benefits of UHMW PE, such as its high durability, low friction coefficient, chemical resistance, and impact strength, make it a highly sought-after material in various industries. Its versatility, coupled with environmental friendliness and cost-effectiveness, further enhances its appeal to manufacturers and consumers alike.

Applications of UHMW PE

From the aerospace sector to medical equipment, UHMW PE's versatility is unmatched. Its applications range from gears and bearings in the automotive industry to liners in material handling systems.

Diverse Applications of UHMW PE in Various Sectors

Ultra-High Molecular Weight Polyethylene (UHMW PE) is a highly versatile material used in a wide range of applications across Europe and America. Its unique properties make it suitable for various industries, from defense to sports equipment.

Defense and Military Applications

In the defense sector, UHMW PE is used for its outstanding impact resistance and energy absorption capabilities. It is utilized in the production of protective clothing, helmets, and bulletproof materials. For instance, armored protective plates for helicopters, tanks, and ships, as well as bulletproof vests and stab-resistant vests, are made from UHMW PE. Its effectiveness in these applications is highlighted by its widespread use in the American bulletproof vest market.

Aerospace and Aviation

In aerospace engineering, UHMW PE's light weight, high strength, and impact resistance make it ideal for various aircraft components. It is used in wingtip structures, spaceship structures, and buoy aircraft. Additionally, it serves as a material for deceleration parachutes in space shuttles and heavy object suspension ropes in aircraft, replacing traditional steel cables and synthetic fiber ropes.

Marine and Nautical Applications

UHMW PE is extensively used in marine engineering for ropes, cables, sails, and fishing gear. Its high strength and corrosion resistance make it suitable for negative force ropes, heavy load ropes, rescue ropes, towing ropes, sailing ropes, and fishing lines. The material's properties solve issues like corrosion, hydrolysis, and UV degradation encountered with steel cables and nylon or polyester cables in marine environments.

Sports Equipment

In the sports industry, UHMW PE is used to manufacture helmets, skis, windsurfing boards, fishing rods, rackets, bicycles, gliding boards, and ultra-lightweight aircraft parts. Its performance surpasses traditional materials, offering enhanced durability and safety in sports equipment.

Medical and Biomedical Applications

UHMW PE's biocompatibility makes it suitable for medical implants, dental tray materials, and plastic sutures. It does not cause allergies and is used in clinical applications. Additionally, it is employed in the production of medical gloves and other protective gear.

Industrial and Construction Uses

In the industrial sector, UHMW PE and its composites are used for pressure-resistant containers, conveyor belts, automobile buffer plates, and as reinforced cement composite materials in construction. These applications benefit from the material's toughness and impact resistance.

Everyday and Consumer Products

UHMW PE finds applications in everyday products like cycle seats, tents, tarps, backpacks, sailing lines, sailcloth, hammocks, and cut-resistance skate suits. Its versatility and durability make it a preferred material for these consumer products.

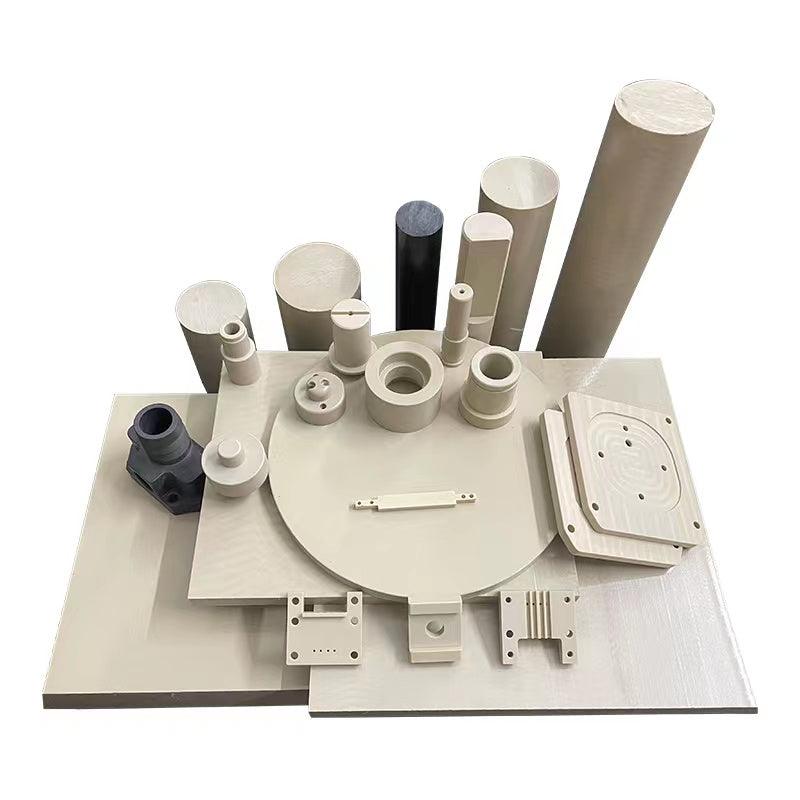

Custom Fabrication and Solutions

At Bee Plastic, we offer bespoke solutions. Our CNC machining, thermoforming, and injection molding services cater to your specific industry needs.

Bee Plastic's Custom Fabrication Excellence in UHMW PE

At Bee Plastic, we specialize in custom fabrication solutions for UHMW PE, catering to a diverse range of industries across Europe and America. Our expertise lies in transforming this versatile material into tailored products that meet specific industry requirements.

Advanced CNC Machining for Precision and Quality

Our state-of-the-art CNC machining services allow us to create UHMW PE parts with exceptional precision. Whether it's intricate components for the medical industry or robust parts for the mining sector, our CNC machining process ensures high-quality, consistent results. This technology enables us to produce everything from prototypes to large-scale production runs, meeting the exact specifications of our clients.

Custom Extrusion Capabilities

We offer custom extrusion services for UHMW PE, providing unique profiles for various applications. Our capabilities include co-extrusion and tri-extrusion, allowing for the creation of complex shapes and multi-material products. This flexibility is particularly beneficial for industries like automotive, where custom profiles are essential for specific parts and systems.

Reinforced Tubing and Layflat Tubing Solutions

Our reinforced and layflat tubing solutions in UHMW PE are designed for durability and performance. These custom tubing options are ideal for applications in material handling, wire and cable management, and industrial sectors, where strength and resistance to wear are crucial.

Overcoating and Custom Chuting

Bee Plastic's overcoating services enhance the properties of UHMW PE parts, providing additional protection against wear and environmental factors. Our custom chuting solutions are tailored for industries like mining and agriculture, where efficient and durable material handling systems are vital.

Meeting the Needs of Diverse Industries

Our custom fabrication services extend to a wide range of industries, including military & defense, automotive, conveyor systems, geophysical applications, and more. We understand the unique challenges of each sector and provide customized UHMW PE solutions that address these specific needs.

Collaborative Design and Development

At Bee Plastic, we believe in a collaborative approach to design and development. We work closely with our clients to understand their requirements and provide solutions that not only meet but exceed their expectations. Our team of experts is dedicated to delivering innovative and effective UHMW PE products that align with our clients' goals.

Industries Served

- Aerospace: For components that demand high strength and low weight.

- Automotive: In parts requiring durability and wear resistance.

- Medical: For non-toxic, sterilizable equipment components.

- Food and Beverage: Ideal for non-contaminating surfaces.

Bee Plastic's UHMW PE Solutions Across Diverse Industries

Bee Plastic's expertise in UHMW PE extends to a wide range of industries, demonstrating our ability to provide custom solutions tailored to the unique needs of different sectors in Europe and America.

Food Processing and Handling

In the food processing industry, UHMW PE's FDA compliance and resistance to water absorption make it an ideal material for machinery components. Our custom solutions include parts for food filling devices and conveyor systems, ensuring safety and efficiency in food production.

Environmental and Water Treatment

Our UHMW PE solutions are extensively used in environmental barrier components and water treatment plants. The material's resistance to wear and non-reactivity with water make it perfect for dam gates, water treatment facilities, and other applications where durability in wet conditions is crucial.

Paint and Pigment Equipment

In the paint and pigment industry, UHMW PE's abrasion resistance is a key asset. We provide custom parts for equipment that handle abrasive and viscous media, ensuring long-lasting performance in these challenging environments.

Pulp and Paper Processing

The pulp and paper industry benefits from our UHMW PE solutions, particularly in parts that require resistance to wear and chemicals. Our custom components are designed to withstand the rigorous processes involved in paper production.

Aerospace and Aviation

Our expertise extends to the aerospace and aviation sectors, where UHMW PE's lightweight and high-strength properties are invaluable. We fabricate components for aircraft and space shuttles, contributing to the safety and efficiency of these advanced machines.

Marine Engineering

In marine engineering, UHMW PE's corrosion resistance and strength are essential. We provide custom solutions for ropes, cables, and other marine applications, ensuring durability and performance in harsh marine environments.

Industrial Machinery and Construction

Bee Plastic's UHMW PE solutions are critical in industrial machinery and construction. Our custom fabrication services cater to the production of heavy-duty machinery parts and construction materials, where the material's toughness and impact resistance are vital.

Medical and Pharmaceutical Equipment

The medical and pharmaceutical industries rely on our UHMW PE solutions for their biocompatibility and safety. We produce custom parts for medical implants, dental trays, and pharmaceutical equipment, adhering to the highest standards of quality and safety.

Comparison with Alternatives

While materials like HDPE and LDPE have their uses, UHMW PE excels in durability and performance, making it a cost-effective choice in the long run.

Superiority of UHMW PE Over Alternatives at Bee Plastic

At Bee Plastic, we emphasize the superiority of Ultra-High Molecular Weight Polyethylene (UHMW PE) over alternative materials, showcasing its unique benefits in various applications. This comparison is particularly relevant in the European and American markets, where material performance is critical.

UHMW PE vs. HDPE (High-Density Polyethylene)

- Impact Resistance: UHMW PE has a significantly higher impact resistance compared to HDPE. This makes it more suitable for applications where durability under stress is crucial.

- Wear Resistance: UHMW PE exhibits exceptional wear resistance, outperforming HDPE in applications involving abrasion and friction.

-

Applications: While HDPE is commonly used for containers and piping, UHMW PE's superior strength and durability make it ideal for more demanding applications like industrial gears and liners.

UHMW PE vs. Other Thermoplastics

- Abrasion Resistance: UHMW PE stands out with its extremely high abrasion resistance when compared to other thermoplastics, making it the preferred choice for heavy-duty applications.

- Chemical Resistance: Its resistance to a wide range of chemicals surpasses that of many other plastics, ensuring longevity in harsh environments.

Custom Fabrication Advantages with UHMW PE

- Machinability: UHMW PE's ease of machining allows for precise custom fabrication, a key advantage offered by Bee Plastic. This enables the creation of bespoke components that precisely meet customer specifications.

- Versatility: The versatility of UHMW PE in fabrication is unmatched, allowing for a wide range of products, from intricate medical devices to robust industrial parts.

Environmental Impact and Sustainability

- Recyclability: UHMW PE is recyclable, aligning with modern sustainability practices. Its long lifespan also means less frequent replacement, reducing environmental impact over time.

- Energy Efficiency in Production: The production process of UHMW PE is more energy-efficient compared to some alternatives, further emphasizing its environmental benefits.

Customer Testimonials and Case Studies

Hear from our satisfied clients across various industries about how UHMW PE from Bee Plastic has revolutionized their operations.

Transforming Industries with UHMW PE: Client Success Stories

At Bee Plastic, our commitment to providing high-quality UHMW PE solutions has positively impacted various industries. Here, we share some of our client testimonials and case studies that highlight the versatility and effectiveness of UHMW PE.

Revolutionizing the Food Processing Industry

- Case Study: A major food processing company faced challenges with their conveyor system, experiencing frequent wear and tear. After switching to UHMW PE components provided by Bee Plastic, they reported a significant reduction in maintenance costs and downtime. The self-lubricating and wear-resistant properties of UHMW PE ensured smoother operations and longer-lasting performance.

- Client Testimonial: "The switch to UHMW PE parts was a game-changer for our production line. We've seen a remarkable decrease in maintenance needs, thanks to Bee Plastic's high-quality components." - Food Processing Plant Manager

Enhancing Environmental and Water Treatment Facilities

- Case Study: A water treatment facility was struggling with corrosion and wear in their dam gates. Bee Plastic provided custom-fabricated UHMW PE gates, which exhibited excellent corrosion resistance and durability. The facility reported improved performance and reduced repair costs.

- Client Testimonial: "Bee Plastic's UHMW PE solutions have significantly improved our facility's efficiency. The material's resistance to harsh conditions is outstanding." - Environmental Engineer

Advancements in Aerospace and Aviation

- Case Study: An aerospace company required lightweight yet strong components for their aircraft. Bee Plastic's UHMW PE parts offered the perfect balance of lightness and strength, leading to enhanced aircraft performance and fuel efficiency.

- Client Testimonial: "The UHMW PE components from Bee Plastic have contributed greatly to our aircraft designs, providing both durability and weight reduction." - Aerospace Design Engineer

Breakthroughs in Marine Engineering

- Case Study: A marine engineering firm needed robust materials for ropes and cables used in harsh sea conditions. UHMW PE products from Bee Plastic demonstrated superior strength and corrosion resistance, outperforming traditional materials.

- Client Testimonial: "We've been impressed with the performance of UHMW PE in our marine applications. It withstands the challenging marine environment exceptionally well." - Marine Project Manager

Impact on Industrial Machinery and Construction

- Case Study: A construction company was facing issues with heavy-duty machinery parts wearing out quickly. Bee Plastic's UHMW PE parts, known for their toughness and impact resistance, provided a long-lasting solution, reducing the frequency of replacements.

- Client Testimonial: "The durability of UHMW PE parts from Bee Plastic has been a major benefit for our construction machinery. We've seen a noticeable improvement in the lifespan of our equipment." - Construction Site Supervisor

FAQs about UHMW PE

We address your queries, from technical specifications to environmental impact, ensuring you make an informed decision.

Frequently Asked Questions About UHMW PE at Bee Plastic

What is UHMW PE?

UHMW PE stands for Ultra-High Molecular Weight Polyethylene. It is a type of thermoplastic polymer known for its high molecular weight, which gives it excellent properties like extreme durability, high impact resistance, and low friction.

How does UHMW PE compare to other plastics?

UHMW PE is superior to many other plastics due to its higher abrasion resistance, impact strength, and lower coefficient of friction. It outperforms materials like HDPE (High-Density Polyethylene) in demanding applications.

What are the typical applications of UHMW PE?

UHMW PE is used in a variety of applications, including industrial gears, liners, conveyor systems, and medical devices. Its versatility makes it suitable for industries ranging from food processing to aerospace.

Is UHMW PE suitable for use in food processing equipment?

Yes, UHMW PE is FDA compliant and is often used in food processing and handling due to its non-toxic nature and resistance to water absorption.

Can UHMW PE be used in high-temperature applications?

UHMW PE has a limited upper use temperature of around 180°F (82°C). It is suitable for many applications but may not be ideal for high-temperature environments.

How does Bee Plastic customize UHMW PE products?

At Bee Plastic, we specialize in custom fabrication of UHMW PE products. Our state-of-the-art CNC machining and extrusion capabilities allow us to create precise, tailored solutions for various industries.

What makes UHMW PE environmentally friendly?

UHMW PE is recyclable and has a long lifespan, reducing the need for frequent replacements. Its production is also more energy-efficient compared to some alternative materials.

Elevate Your Projects with Custom UHMW PE Solutions from BeePlastic

Interested in learning more or ready to order? Contact us today for a consultation or quote.

Unleash the Potential of Custom UHMW PE Solutions

At BeePlastic, we're not just offering materials; we're unlocking possibilities. With our custom Ultra-High Molecular Weight Polyethylene (UHMW PE) solutions, your next big innovation is just a step away.

Take the First Step Towards Innovation

Don't let standard solutions limit your potential. Embrace the extraordinary with BeePlastic's custom UHMW PE. Whether you're in aerospace, marine engineering, or food processing, our tailored solutions are designed to meet your unique needs. Contact us today to start your custom UHMW PE journey.

Discover the Unmatched Benefits of UHMW PE

Experience the unparalleled durability, exceptional wear resistance, and outstanding impact strength of UHMW PE. These properties make it the ideal choice for challenging environments and demanding applications. Learn more about how UHMW PE can revolutionize your industry.

Join a Community of Forward-Thinkers

You're not just choosing a material; you're joining a network of innovators and industry leaders. Become part of the BeePlastic community and lead the way in material innovation. Share your challenges with us, and let's craft a solution together.

Your Vision, Our Expertise

Every project is a new horizon. Share your vision with us, and let our experts tailor a solution that brings it to life. With BeePlastic's custom UHMW PE, your vision becomes a reality. Let's collaborate to create something exceptional.

Ready to Transform Your Industry?

The future waits for no one. Act now and be the pioneer in your field with BeePlastic's UHMW PE solutions. Reach out to us, and let's discuss how we can elevate your projects beyond the ordinary.

Easy Contact for Quick Solutions

Getting in touch is just a click away. Visit our contact page and connect with our UHMW PE specialists. We're here to answer your questions and guide you through the process of custom solution development.

Commitment to Excellence

Choose BeePlastic and experience our commitment to quality, innovation, and customer satisfaction. Start your journey with us and see why BeePlastic is the preferred choice for custom UHMW PE solutions.

Additional Resources

Explore our technical datasheets and educational materials for an in-depth understanding of UHMW PE.

Additional Resources on UHMW PE (HMPE)

Understanding UHMW PE's Unique Properties

UHMW PE, also known as HMPE, is a standout material in the field of thermoplastics. Its long molecular chains enhance its strength and impact resistance, making it an ideal choice for demanding applications. This material is not only resistant to concentrated acids and alkalis but also to a wide range of organic solvents. Its low moisture absorption and low coefficient of friction are noteworthy, as is its self-lubricating nature. These properties make UHMW PE (HMPE) highly suitable for applications where durability and resistance to wear and abrasion are critical.

Industrial and Medical Applications

UHMW PE's versatility extends to various industrial and medical applications. In the industrial sector, it's used in the automotive and bottling industries, among others, due to its wear and impact resistance. In the medical field, UHMW PE has been the material of choice for joint arthroplasty in orthopedic and spine implants since the 1960s. Its biocompatibility and durability make it an excellent choice for these applications.

Innovations and Future Prospects

The development of UHMW PE fibers, such as Dyneema and Spectra, has opened new avenues in ballistic protection, defense, and even in the medical devices industry. These fibers are known for their exceptional strength and lightweight properties, making them ideal for a range of high-performance applications. The ongoing research and development in this field suggest a bright future for UHMW PE (HMPE) in both existing and novel applications.

For more detailed information and to explore the full range of applications and properties of UHMW PE (HMPE), you can refer to authoritative sources such as academic journals, industry publications, and material science textbooks. These resources provide in-depth insights into the material's characteristics, processing methods, and evolving uses in various industries.

Choose Bee Plastic for UHMW PE solutions that promise quality, durability, and innovation.

Embracing the Versatility of UHMW PE

UHMW PE: A Material of Many Names

UHMW PE, known for its exceptional strength and durability, goes by various names across different regions and applications. In Europe and America, it's not just UHMWPE or UHMW, but also High-Modulus Polyethylene (HMPE), Dyneema, and Spectra, among others. This versatility in naming reflects its wide-ranging uses and the trust industries place in its capabilities.

The Global Reach of UHMW PE

From the medical field to heavy-duty industrial applications, UHMW PE's presence is global. Its alternative names like TIVAR and Polystone-M are not just labels but symbols of quality and reliability in the material. This global recognition underscores the importance of understanding the various terminologies associated with UHMW PE, especially for businesses looking to expand their reach in international markets.

Why Choose UHMW PE?

Choosing UHMW PE means investing in a material known for its high impact strength, resistance to abrasion, and low friction properties. Whether it's in the form of fibers like Dyneema and Spectra or as consolidated materials like TIVAR and Polystone-M, UHMW PE stands out as a superior choice for a multitude of applications. Its adaptability and strength make it an ideal choice for industries ranging from defense to healthcare.

Connect with Us for UHMW PE Solutions

Understanding the diverse applications and names of UHMW PE is crucial for making informed decisions. If you're looking for a reliable supplier or wish to learn more about how UHMW PE can benefit your business, contact us. Our expertise in UHMW PE, coupled with a global perspective, positions us to provide you with the best solutions tailored to your needs. Reach out today and explore the possibilities with UHMW PE.

Explore Our Material Selection

In addition to current materials, we offer sales and processing services for a variety of materials. Click on the name of a material below to learn more about its properties and applications:

| Material Name | Full Name | Applications | Properties |

|---|---|---|---|

| HDPE | High-Density Polyethylene | Piping, Bottles | High Strength-to-Density Ratio |

| UHMW-PE | Ultra-High-Molecular-Weight Polyethylene | Conveyor Belts, Bearings | Extremely High Wear Resistance |

| Nylon | Polyamide | Gears, Bearings | High Mechanical Strength, Good Wear Resistance |

| PI | Polyimide | Flexible Printed Circuits | High Heat Resistance |

| PEI | Polyetherimide | Medical Devices, Aircraft Interiors | High Strength, Flame Resistance |

| PEEK | Polyether Ether Ketone | Aerospace Parts, Medical Implants | High Temperature and Chemical Resistance |

| PP | Polypropylene | Packaging, Textiles | Chemical Resistance, Elasticity |

| PET | Polyethylene Terephthalate | Beverage Bottles, Food Containers | High Strength, Thermoformability |

| PAI | Polyamide-imide | Automotive Components, Electrical Insulation | High Strength, Thermal Stability |

| Acrylic | Polymethyl Methacrylate (PMMA) | Displays, Lenses | Transparency, Weather Resistance |

| PTFE | Polytetrafluoroethylene | Non-Stick Coatings, Gaskets | Low Friction, Chemical Resistance |

| POM | Polyoxymethylene (Acetal) | Precision Parts, Gears | High Stiffness, Low Friction |

| PC | Polycarbonate | Safety Glasses, CDs | High Impact Resistance, Transparency |

| PPS | Polyphenylene Sulfide | Automotive Parts, Electronics | High Temperature Resistance, Chemical Stability |

| PVC | Polyvinyl Chloride | Pipes, Cable Insulation | Durability, Chemical Resistance |

| PVDF | Polyvinylidene Fluoride | Chemical Processing Equipment | High Chemical Resistance, Purity |

| PU | Polyurethane | Foam Seating, Insulation Panels | Flexibility, Durability |

| FR-4(G10) | Flame Retardant Glass-Reinforced Epoxy Laminate | Printed Circuit Boards | Flame Resistance, Mechanical Strength |

| Bakelite | Phenol Formaldehyde Resin | Electrical Insulators, Radio Casings | High Mechanical Strength, Heat Resistance |

| ABS | Acrylonitrile Butadiene Styrene | Automotive, Electronics, Medical Devices | Durable, Impact Resistant, Easy to Machine |

Learn More

Fully Customizable to Your Specifications

At BeePlastic, we offer precision cutting and machining to produce sheets and rods that perfectly fit your project's specific dimensions and requirements.

Tailored Solutions Across Industries

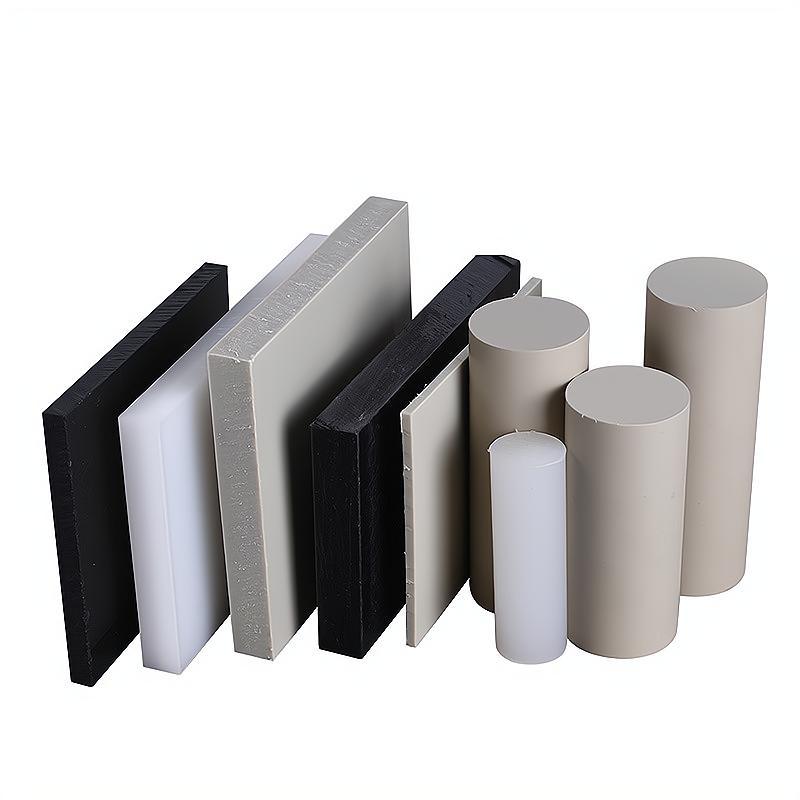

Explore Our Full Range of Plastic Materials

Discover the versatility and quality of our extensive plastic materials portfolio. From standard sheets to highly specialized rods, each product is designed to meet the diverse needs of industries including aerospace, automotive, and healthcare. Browse our collection to find the perfect material suited to your project requirements.

Browse Our Material Catalog