Dive into the transformative world of PEEK sheets and discover why they are revolutionizing the accessory manufacturing industry in our latest blog post, "Why PEEK Sheets Are a Game-Changer for Accessory Manufacturers: Insider Insights." This comprehensive guide begins with an Introduction to PEEK Sheets, unraveling the basics and unique properties that set them apart in the world of materials. We'll explore the Superior Properties of PEEK Sheets for Accessory Design, highlighting their unparalleled high temperature resistance, chemical resistance, and mechanical strength — qualities that promise durability and versatility in accessory production.

Our journey doesn't stop there. Delve into Innovative Uses of PEEK Sheets in the Accessory Industry, where we showcase cutting-edge applications and how leading manufacturers are leveraging PEEK sheets to create groundbreaking products. The guide also offers practical Procurement Tips for Sourcing High-Quality PEEK Sheets, ensuring you know how to navigate the complexities of material selection and secure the best materials at competitive prices.

We address the Challenges and Solutions in Working with PEEK Sheets, providing valuable insights into overcoming common obstacles in machining and finishing, ensuring your manufacturing process is as smooth as the PEEK surface itself. Lastly, we look towards the future in The Future of Accessory Manufacturing: PEEK Sheets Leading the Way, forecasting how PEEK sheets will continue to shape the industry with advancements in sustainability and technology.

Join us as we unveil the secrets behind PEEK sheets and their pivotal role in setting new standards for quality, innovation, and efficiency in accessory manufacturing. Whether you're a seasoned manufacturer or a curious newcomer, this blog post will equip you with insider insights and expert advice to harness the full potential of PEEK sheets in your next project.

Introduction to PEEK Sheets: Understanding the Basics

In the realm of advanced materials that have significantly impacted the manufacturing sector, PEEK sheets stand out for their remarkable properties and versatility. This introduction aims to unfold the layers of PEEK (Polyether ether ketone), a high-performance thermoplastic, highlighting its composition, durability, and the pivotal role it plays in producing high-quality accessories. By diving deep into the essence of PEEK sheets, manufacturers and designers can better understand how to leverage this material's full potential.

What are PEEK Sheets?

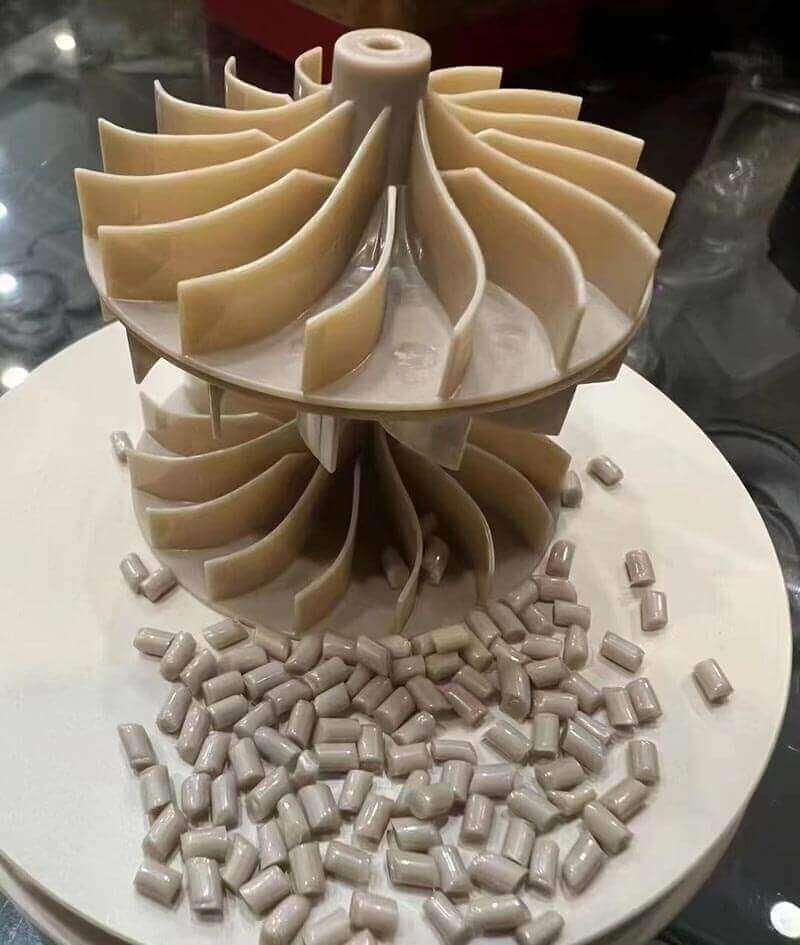

PEEK sheets are fabricated from Polyether ether ketone, a semi-crystalline thermoplastic known for its excellent mechanical and chemical resistance properties. The material boasts a high melting point (around 343°C or 662°F), which makes it exceptionally resistant to thermal degradation. This resilience to high temperatures, coupled with its ability to maintain stiffness and strength across a wide range of temperatures, positions PEEK sheets as a prime choice for applications requiring robust performance in harsh environments.

The Composition of PEEK Sheets

At the molecular level, PEEK is composed of aromatic rings linked by ether and ketone groups. This unique structure contributes to its outstanding thermal stability, chemical resistance, and mechanical strength. PEEK sheets are produced through various processes, including extrusion and compression molding, allowing for versatility in thickness and size to suit different application needs.

Durability and Performance

The durability of PEEK sheets is unparalleled, with excellent wear and abrasion resistance, making them suitable for applications where longevity and reliability are critical. Their resistance to a broad spectrum of chemicals, including hydrocarbons, acids, and solvents, ensures that PEEK sheets maintain their integrity in corrosive environments, further extending their lifespan.

Preferred Choice in the Manufacturing Sector

PEEK's exceptional properties make it a preferred choice in the manufacturing sector, especially for high-quality accessories. Industries such as aerospace, automotive, and medical devices rely on PEEK sheets for components that demand high performance under extreme conditions. The material's lightweight nature, combined with its strength, offers significant advantages over metals and other plastics, enabling innovation in design and functionality.

Manufacturers appreciate PEEK sheets not only for their performance but also for their ease of processing. Despite their high melting point, PEEK can be machined, welded, and even 3D printed, offering flexibility in manufacturing processes. This adaptability, along with the material's inherent properties, opens up a world of possibilities for creating complex shapes and designs that were previously unattainable.

Why They're Preferred for High-Quality Accessories

In the accessory manufacturing industry, PEEK sheets are particularly valued for their aesthetic and functional qualities. They can be engineered to exhibit various colors and finishes, enhancing the visual appeal of the final product. Moreover, their resistance to UV light ensures that products do not degrade or discolor over time, maintaining their appearance and functionality.

By choosing PEEK sheets for accessory production, manufacturers can deliver products that stand the test of time, both in terms of physical durability and style. The material's versatility extends to applications ranging from luxury watch components to high-end automotive interior parts, where performance and aesthetics go hand in hand.

Through this exploration of PEEK sheets, it's clear that their fundamental properties of composition, durability, and adaptability make them a superior choice in the manufacturing landscape. The ability to withstand challenging conditions while providing flexibility in design and application underscores why PEEK sheets are not just a material choice but a strategic advantage for high-quality accessory manufacturing.

The Superior Properties of PEEK Sheets for Accessory Design

When it comes to selecting materials for accessory design, PEEK sheets offer a combination of characteristics that set them apart from other polymers and materials in the market. This section delves into the superior properties of PEEK sheets, such as high temperature resistance, chemical resistance, and mechanical strength, and examines how these attributes provide significant advantages to accessory manufacturers.

High Temperature Resistance

One of the most remarkable properties of PEEK sheets is their high temperature resistance. With a melting point of approximately 343°C (662°F), PEEK can withstand environments that would degrade lesser materials. This resistance to extreme heat is crucial for accessories intended for use in high-temperature applications, such as automotive or aerospace components, where reliability under thermal stress is non-negotiable. For designers, this means the freedom to innovate without the constraints of material limitations, ensuring that the final product maintains its integrity and performance regardless of exposure to high temperatures.

Chemical Resistance

PEEK sheets are also distinguished by their exceptional chemical resistance. This material stands up to a wide range of aggressive chemicals, including hydrocarbons, acids, and solvents, without deteriorating. This characteristic is particularly valuable in the production of accessories that may come into contact with corrosive substances or need to maintain their appearance and functionality in various environments. Whether it's a luxury watch exposed to everyday solvents or medical equipment that must withstand harsh sterilization processes, PEEK's chemical resistance ensures longevity and durability of the final product.

Mechanical Strength

The mechanical strength of PEEK sheets is another attribute that cannot be overstated. PEEK exhibits an excellent strength-to-weight ratio, rivaling that of metals but at a fraction of the weight. Its tensile strength, coupled with high impact resistance, makes it an ideal choice for manufacturing robust, lightweight accessories. This strength does not diminish significantly over a wide range of temperatures, making PEEK suitable for applications requiring structural integrity under variable environmental conditions.

Benefits to Accessory Manufacturers

For accessory manufacturers, the properties of PEEK sheets translate into tangible benefits. The high temperature and chemical resistance allow for the creation of products that can be used in challenging conditions without compromising on quality or performance. This opens up new markets and applications where traditional materials might fail.

Moreover, the mechanical strength of PEEK enables the design of thinner, lighter accessories without sacrificing durability. This is particularly appealing in industries like consumer electronics and automotive, where the demand for lightweight yet strong components is ever-increasing.

Furthermore, PEEK's versatility in processing allows for complex designs that were previously difficult or impossible to achieve with other materials. Manufacturers can utilize various techniques, such as machining, molding, and even 3D printing, to produce intricate parts with precision. This design flexibility, combined with PEEK's superior properties, empowers accessory manufacturers to push the boundaries of innovation, creating products that stand out in the market for their quality, durability, and aesthetic appeal.

By leveraging the superior properties of PEEK sheets, accessory manufacturers can achieve a competitive edge, delivering products that meet the highest standards of performance and design.

Innovative Uses of PEEK Sheets in the Accessory Industry

The unique properties of PEEK sheets have not only challenged traditional manufacturing paradigms but also opened up a plethora of innovative applications within the accessory industry. This versatility and performance superiority of PEEK sheets have enabled manufacturers to explore new horizons, creating products that offer unparalleled durability, functionality, and aesthetic appeal. Let's delve into some of the innovative uses of PEEK sheets in accessory manufacturing, showcasing real-world examples where PEEK's superior qualities shine.

High-Performance Automotive Components

In the automotive sector, PEEK sheets are revolutionizing the production of high-performance components. From under-the-hood parts to interior elements, PEEK's high temperature and chemical resistance make it an ideal material for applications that require durability and reliability under extreme conditions. For example, custom gear knobs, ventilation system components, and electrical connector housings made from PEEK not only withstand the rigors of automotive environments but also contribute to weight reduction, enhancing vehicle performance and fuel efficiency.

Luxury and High-Tech Watchmaking

The world of luxury watchmaking has found a valuable ally in PEEK sheets. Given their excellent mechanical strength and resistance to chemicals and wear, PEEK is increasingly being used to craft intricate watch components, such as movement holders and casing parts. This application not only capitalizes on PEEK's durability but also its ability to be precision machined into complex shapes, allowing for the creation of watches that stand the test of time, both mechanically and aesthetically.

Advanced Medical Devices and Equipment

PEEK's biocompatibility and resistance to sterilization processes make it a preferred choice in the medical accessory industry. Surgical tools, implantable devices, and components for diagnostic equipment made from PEEK sheets exemplify how this material's properties can be leveraged to improve patient outcomes and streamline medical procedures. Instruments like endoscopic surgery accessories benefit from PEEK's lightweight and radiolucent properties, allowing for more precise and less invasive procedures.

Aerospace Components

The aerospace industry benefits significantly from the application of PEEK sheets in manufacturing lightweight, high-strength components. From interior cabin elements such as seat frames and overhead compartments to insulation components in electrical systems, PEEK's thermal stability and flame retardance ensure safety and performance at high altitudes. These applications underscore PEEK's ability to meet the stringent regulations and performance demands of the aerospace sector.

Consumer Electronics

In the consumer electronics industry, PEEK sheets are making waves in the design and manufacturing of durable, high-quality parts. The material's excellent electrical insulation properties and resistance to wear and environmental factors make it ideal for components such as smartphone frames, tablet stands, and laptop hinges. These PEEK-based accessories not only enhance the device's longevity but also its user experience by offering a premium feel combined with lightweight and durability.

Sporting Goods

The sporting goods sector is leveraging PEEK for its strength-to-weight ratio and impact resistance, creating accessories that enhance athletic performance. High-end sports equipment, such as bicycle components, racquet frames, and protective gear, benefit from PEEK's durability and lightweight, providing athletes with an edge in both competitive and recreational activities.

Through these innovative applications, PEEK sheets are setting new standards in the accessory manufacturing industry. By harnessing the unique properties of PEEK, manufacturers are able to push the boundaries of what is possible, offering products that offer superior performance, durability, and aesthetic appeal. As technology advances and manufacturing techniques evolve, the potential for PEEK in accessory design and production is bound to expand even further, continuing to transform industries with its remarkable capabilities.

Procurement Tips for Sourcing High-Quality PEEK Sheets

Sourcing PEEK sheets for your manufacturing needs requires a strategic approach to ensure you're getting the best quality material at the most competitive prices. Given the critical role that PEEK sheets play in various high-performance applications, understanding what to look for in suppliers, the significance of different grades and specifications, and mastering negotiation techniques are essential. This guide aims to offer valuable insights into the procurement process, helping you make informed decisions when sourcing PEEK sheets.

Identifying Reputable Suppliers

The first step in sourcing high-quality PEEK sheets is to identify and select reputable suppliers. Look for suppliers with a solid track record of providing high-grade materials. Certifications and accreditations, such as ISO certification, can be good indicators of a supplier's commitment to quality. Additionally, consider suppliers who are transparent about their sourcing and manufacturing processes, as this openness can be a good sign of reliability and quality assurance.

Understanding Grades and Specifications

PEEK sheets come in various grades, each tailored for specific applications. From general-purpose grades suitable for mechanical and structural components to more specialized grades designed for high-temperature or medical applications, understanding the different specifications is crucial. It's essential to work closely with your supplier to match the grade of PEEK sheet with your application's specific requirements. Factors such as mechanical strength, thermal resistance, and biocompatibility should guide your selection process to ensure optimal performance and compliance with industry standards.

Evaluating Quality and Consistency

Quality and consistency are paramount when sourcing PEEK sheets. Request samples and perform tests to assess the material's properties and ensure they meet your application's demands. Consistent quality across batches is essential for maintaining the integrity of your products. Engage with suppliers who employ rigorous quality control measures and can provide detailed documentation and traceability for their products.

Negotiating the Best Prices

Negotiating the best prices without compromising quality requires a delicate balance. Educate yourself on the market trends and the factors influencing PEEK sheet prices, such as raw material costs and demand fluctuations. A long-term relationship with a supplier can often lead to better pricing and terms, as suppliers value loyalty and consistent business. Don't hesitate to discuss volume discounts or to negotiate payment terms that can offer financial flexibility. However, remember that the lowest price is not always synonymous with the best value. Factor in the quality, reliability, and support services that the supplier offers.

Sustainability and Ethical Sourcing

In today's market, sustainability and ethical sourcing are increasingly important. Partner with suppliers who prioritize environmentally friendly practices and ethical sourcing in their procurement of raw materials. This commitment not only aligns with global sustainability goals but can also enhance your brand's reputation among environmentally conscious consumers.

Building Strong Supplier Relationships

Finally, building strong, collaborative relationships with your PEEK sheet suppliers can lead to better service, support, and pricing. Open communication, transparency, and mutual respect are key to developing partnerships that can adapt to market changes and support your business's growth.

By following these procurement tips, manufacturers can source high-quality PEEK sheets that meet their specific needs without compromising on quality or value. Understanding the market, engaging with reputable suppliers, and fostering strong supplier relationships are critical steps in securing the best materials for your manufacturing processes.

Challenges and Solutions in Working with PEEK Sheets

Working with PEEK sheets presents a unique set of challenges, given their high-performance properties. However, these challenges are not insurmountable. With the right knowledge and techniques, manufacturers can efficiently machine, join, and finish PEEK sheets, leveraging their superior qualities to the fullest. This section explores common obstacles in working with PEEK sheets and offers expert advice on overcoming these hurdles.

Machining PEEK Sheets

Challenge: Preserving Material Integrity

Machining PEEK sheets requires precision to preserve the material's integrity, as its high melting point and toughness can lead to difficulties in machining without proper equipment.

Solution: Optimizing Machining Parameters

Using sharp tools specifically designed for high-performance thermoplastics and optimizing machining parameters such as speed, feed rate, and coolant application can significantly improve outcomes. It's crucial to maintain a balance that prevents overheating while ensuring efficient material removal. Implementing CNC machining techniques can offer the precision and control needed to achieve high-quality results.

Joining PEEK Sheets

Challenge: Maintaining Strength at Joint Points

Joining PEEK sheets in a manner that maintains the strength and integrity of the joint points is challenging due to PEEK's high melting point and chemical resistance.

Solution: Advanced Joining Techniques

Adhesive bonding and mechanical fastening are viable methods, but they require careful selection of adhesives and fasteners that are compatible with PEEK's properties. For applications requiring seamless joints, techniques such as laser welding or induction welding, which can heat the PEEK to its melting point without degrading the material, may be utilized. Preparing the surfaces properly and selecting the right joining method based on the application's specific requirements are key.

Finishing Techniques for PEEK Sheets

Challenge: Achieving Desired Aesthetics and Functionality

Finishing PEEK sheets to achieve the desired aesthetics or functionality can be challenging due to the material's resistance to traditional finishing processes.

Solution: Tailored Finishing Processes

Employing specialized finishing techniques that account for PEEK's unique properties is essential. For aesthetic finishes, consider high-precision CNC machining or laser engraving to create detailed textures or designs. For functional finishes, such as enhancing surface wear resistance or promoting adhesion, plasma treatments or chemical etching can modify the surface characteristics without compromising the material's inherent properties. Always test the chosen finishing process on a small scale to ensure compatibility with PEEK.

Overcoming Thermal Management Challenges

Challenge: Managing Thermal Expansion

PEEK's thermal expansion can be a concern in applications where dimensional stability is critical, especially when subjected to wide temperature variations.

Solution: Design Adjustments and Material Selection

Design adjustments that account for thermal expansion, such as incorporating tolerance gaps or selecting reinforced PEEK grades with lower thermal expansion coefficients, can mitigate this issue. Understanding the thermal behavior of PEEK in the context of the intended application is crucial for successful implementation.

Expert Advice for Working with PEEK Sheets

To successfully navigate these challenges, manufacturers should invest in training for their teams on the specific properties and best practices for machining, joining, and finishing PEEK sheets. Collaborating with material suppliers and technology providers can also provide valuable insights and access to the latest advancements in processing techniques.

By addressing the common challenges associated with working with PEEK sheets through informed solutions, manufacturers can fully harness the potential of this remarkable material, creating products that offer exceptional performance and durability.

The Future of Accessory Manufacturing: PEEK Sheets Leading the Way

The trajectory of accessory manufacturing is being reshaped by the innovative use of high-performance materials, with PEEK sheets at the forefront of this transformation. As we look to the future, the role of PEEK in driving advancements in technology, enhancing sustainability, and opening up new markets and applications cannot be overstated. This section explores how PEEK sheets are poised to redefine the accessory manufacturing industry, setting new benchmarks for performance, design, and environmental responsibility.

Advancements in Technology and Material Science

The Rise of Smart Accessories

One of the most exciting prospects for PEEK sheets is their integration into the burgeoning field of smart accessories. With their superior mechanical properties and resistance to environmental factors, PEEK is an ideal candidate for wearable technology and other smart accessories that require durability, lightweight, and biocompatibility. Innovations in miniaturization and sensor integration could see PEEK-based products becoming central to health monitoring, fitness tracking, and augmented reality applications.

Enhanced Manufacturing Techniques

Advancements in manufacturing technologies, such as 3D printing and automated CNC machining, are set to further unlock the potential of PEEK sheets. These technologies enable the creation of complex geometries and bespoke designs with precision and efficiency. As these techniques become more widespread and sophisticated, the ability to rapidly prototype and produce PEEK-based accessories with minimal waste will be a game-changer, reducing time-to-market and fostering innovation.

Emphasizing Sustainability

Circular Economy and Recycling

Sustainability is a critical concern in material selection, and PEEK sheets are well-positioned to contribute to more sustainable manufacturing practices. Efforts to develop recycling methods for PEEK and other high-performance polymers are gaining momentum, aiming to establish a circular economy where material waste is minimized. The durability and long lifespan of PEEK-based products also align with sustainable principles, reducing the need for frequent replacements and the associated environmental impact.

Reducing Carbon Footprint

The lightweight nature of PEEK contributes to energy efficiency, particularly in the automotive and aerospace industries, where reduced weight translates to lower fuel consumption and greenhouse gas emissions. As the focus on reducing carbon footprints intensifies, the demand for lightweight, high-strength materials like PEEK is expected to surge, further solidifying its role in future accessory manufacturing.

Exploring New Markets and Applications

Expanding Beyond Traditional Boundaries

The versatility of PEEK sheets opens up a plethora of opportunities in new and emerging markets. Beyond its established presence in aerospace, automotive, and medical devices, PEEK is making inroads into sectors such as renewable energy, where components for solar panels and wind turbines benefit from its durability and resistance to harsh environmental conditions. Consumer electronics, sports equipment, and even luxury goods are also areas where PEEK's unique properties can offer significant advantages.

The Role of PEEK in Global Challenges

Looking ahead, PEEK sheets are set to play a pivotal role in addressing global challenges. In medical fields, PEEK's biocompatibility and sterilization resistance make it ideal for developing advanced prosthetics and implantable devices, improving patient outcomes. In the quest for more sustainable manufacturing, PEEK's potential for recycling and reusability will be crucial in reducing waste and promoting environmental stewardship.

As we venture into the future of accessory manufacturing, PEEK sheets stand out as a material that not only meets the current demands of the industry but also anticipates future needs. With ongoing advancements in material science and manufacturing technology, coupled with a growing emphasis on sustainability, PEEK is poised to lead the way in innovation, design, and environmental responsibility, shaping the future of accessory manufacturing in profound ways.

As we navigate the evolving landscape of the accessory manufacturing industry, the transformative role of PEEK sheets becomes increasingly clear. With their unmatched blend of high temperature resistance, chemical resilience, and mechanical strength, PEEK sheets are not just meeting the current demands of the industry but are also paving the way for future innovations. From revolutionizing smart accessory development to driving sustainability forward, PEEK sheets stand at the intersection of technology, design, and environmental responsibility. As manufacturers continue to explore and harness the potential of this exceptional material, the future of accessory manufacturing looks not only more innovative but also more sustainable. The journey with PEEK sheets is just beginning, and its full potential is yet to be unleashed, promising a new era of high-performance, durable, and eco-friendly products. The message is clear: embracing PEEK sheets is not just a strategic move for today's manufacturing challenges but a forward-looking investment in the future of accessory design and production.

Ready to elevate your manufacturing game with PEEK sheets? Don't miss out on the opportunity to transform your products. Scroll down to the bottom of the page and fill out our contact form now. Let's innovate together!