Key Properties Making ABS a Strong and Durable Plastic

-

High tensile strength and stiffness - ABS has a tensile strength ranging from 45 to 60 MPa, giving it the ability to resist breakage under load. The high modulus of elasticity lends rigidity and dimensional stability.

-

Resistance to stress cracking - ABS withstands prolonged exposure to stresses and harsh chemicals without cracking or crazing.

-

Heat resistance up to 180°F - Although not for extreme temperatures, ABS maintains its properties through typical heat cycles during production or use.

-

Abrasion and scratch resistance - The sturdy ABS material holds up well to moderate wear and friction over time.

-

Impact strength down to -40°C - Even at freezing temperatures, ABS retains its signature impact resistance and toughness.

ABS Applications Taking Advantage of Strength and Durability

-

Automotive - ABS is commonly used in car interiors like dashboards and door panels, bumper bars, and other parts that must survive vibration and weather extremes.

-

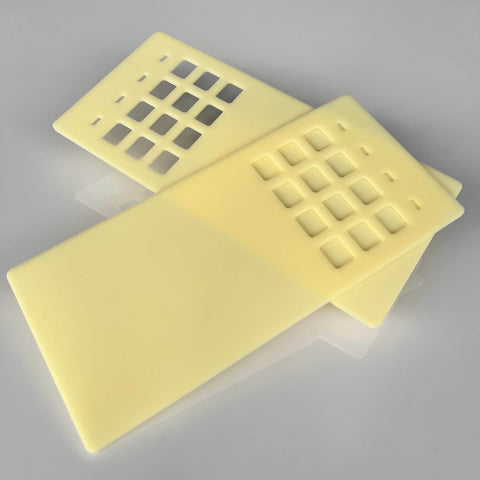

Electronics - Computer keyboards, monitors, printers and other components benefit from the durability and heat resistance of ABS housing and covers.

-

Appliances - ABS sheets stamped into shape make durable refrigerator liners. The material is also used for vacuum cleaner bodies to withstand collision impacts.

-

Toys - ABS is the plastic of choice for LEGO bricks which must couple together securely. It's also used for tough toy vehicles and skateboard decks.

-

Medical Devices - Device housings, diagnostic tools and other components exposed to repeated stresses and cleaning rely on hardwearing ABS plastic.

Key Takeaways on ABS Plastic as a Strong and Durable Choice

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 ABS plastic