FR-4 glass epoxy is the ubiquitous printed circuit board (PCB) material used extensively across global electronics and technology manufacturing. Its versatile electrical, mechanical, and thermal properties facilitate diverse applications serving consumer and industrial needs alike.

This article explores FR-4 material adaptability enabling usage across sectors — from electronics to aerospace, telecommunications to medical, and beyond. We’ll uncover what makes FR-4 substrates so versatile, review established and emerging applications, and consider sustainability impacts of this pervasive technology material.

An Introduction to FR-4 Glass Epoxy Circuit Board Substrates

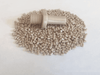

FR-4 copper clad laminates refer to the glass fabric reinforced epoxy resin sheets formed with copper foil on one or both sides. The composite material was developed as an electrical insulator PCB substrate with heat resistance superior to commoditized phenolic resin boards.

Modern FR-4 circuit board materials have evolved to offer reliable physical, electrical, and mechanical properties balanced to meet most application needs with cost-effective manufacturability. This combination of capabilities and affordable production has facilitated global proliferation across sectors requiring durable printed circuit boards.

include:

- Reliable insulator with high dielectric withstand voltage

- Controlled dielectric constant for impedance matching

- Low moisture absorption for dimensional stability

- Good flexural and tensile strength

- Excellent solderability and adhesion with copper foil

- High temperature resistance before delamination or decomposition

- Flame retardancy per safety standards like UL 94 V-0

- RoHS compliant manufacturing without hazardous substances

Of course, specialty substrates like ceramic, Teflon, and others offer distinct property advantages in specific high frequency, thermal, or mechanical load applications. But FR-4 material combines a balanced electrical, thermal, and physical property set for versatility meeting most circuit needs at scale.

Myriad Applications Across Electronics Manufacturing

The electronics industry pioneered early FR-4 adoption for consumer appliance controls and military electronics. Usage expanded exponentially with the ICT revolution.

FR-4 copper clad laminates now suit most PCB fabrication needs — from simple low layer count consumer electronics to complex multi-layer boards packed with next-gen components. Applications include:

- Consumer electronics

- Mobile phones

- Computer motherboards

- Home appliance control boards

- Automotive electronics

- Engine control units

- Infortainment and telematics systems

- Advanced driver assistance sensors

- Industrial equipment

- Programmable logic controllers

- Process management modules

- Machine vision and robotics

- Medical devices

- Patient monitors

- Diagnostic imaging systems

- Therapeutic equipment

This broad applicability results from reliable electrical and physical properties even under challenging operating conditions:

- Stable functionality across temperature swings from -65°C to +170°

- Withstands mechanical vibrations with good flexural and tensile strength

- Dependable even in high moisture environments thanks to dimensional stability

In particular, the FR-4 dielectric constant tuned around 4.5 enables impedance control for matched transmission line characteristics from MHz to GHz frequencies in RF and digital circuits alike. This facilitates integration of higher speed interfaces up to multi-Gbps SerDes, PCIe, USB 3.x, HDMI, and emerging standards.

The FR-4 loss tangent below 0.025 supports low signal loss through critical high frequency pathways. Careful material and manufacturing process controls also minimize detrimental issues like resin reversion.

Aerospace and 5G Telecom Signal FR-4 Advancements

Aviation, satellite, and defense programs push electronics innovation with extreme environmental demands. Commercial 5G networks enable massive wireless data capacity expansion. These applications represent FR-4 adjacency developments for densified high frequency circuits.

Aerospace engineering domains now harness enhanced FR-4 materials to withstand:

- Wide temperature extremes from -70°C to over +180°

- Intense vibrational forces during thrust and maneuvers

- Minimal outgassing in vacuum environments

High frequency boards for 5G Sub-6GHz and mmWave signals also adopt lower loss FR-4 formulations or inorganic filled composites for:

- Stable radio frequency response past 6GHz

- Balanced dielectric constant and loss tangent

- Improved signal integrity at multi-Gbps serial transmissions

While niche substrates and additive processes suit extreme performance requirements, innovated FR-4 materials sufficiently meet most needs. The accessibility and established manufacturing processes make this practical compared to costly specialty materials needing process adaptations.

Spanning Industries Thanks to Material Versatility

Beyond widespread electronics applications, FR-4’s balanced mechanical and electrical properties facilitate diverse industrial usages. Applications include:

Medical Devices

- Diagnostic imaging scanner hardware

- Patient monitoring systems

- Therapeutic devices like dialysis

Instrumentation & Testing Equipment

- Sensor signal conditioning

- Data aggregation and process controllers

- Protocol transformation interfaces

Automation & IoT Products

- Environment sensors for agriculture

- Machine interface boards

- Predictive maintenance modules

Solar Photovoltaics

- Optimized lighting fixture controllers

- Grid tied inverter circuitry

- Charge controllers and energy storage

Industrial Power & EV Charging

- Charging station metering

- High voltage protection

- Power factor correction hardware

Broadcast Media Gear

- Digital signage playback

- Mixing boards and codecs

- HD AV signal distribution

This adaptability across industries results from the fundamental FR-4 electrical insulation, environmental hardiness, and fabrication capabilities that enable customized PCB solutions.

While industry or application specific substrate choices offer optimization (ex. RF materials in telecom, flexible boards for wearables), FR-4 stands out with accessibility and versatility.

Pursuing Sustainability With FR-4 Manufacturing

Electronics hardware sustainability encompasses multiple dimensions — from materials extraction, production impacts, energy consumption, and end-of-life considerations.

FR-4 offers advantages as likely the most responsibly manufactured mainstream PCB substrate option:

Chemical Safety

- RoHS compliant processes avoid lead, cadmium and other harsh substances

- Halogen-free variants eliminate bromine and chlorine releasing dioxins when burned

Responsible Production

- Rigorous quality controls prevent losses from defects

- High yields maximize material utilization

Waste Management

- Recyclability of glass/resin materials in some areas

- Options to recover copper content

While zero waste manufacturing remains an aspirational goal, conscientious FR-4 material usage and recycling represent important progress as electronics proliferate globally. Regulatory pressures also continue driving supply chain responsibility from mining to production to end-of-life material recovery.

Conclusion

As explored here, the incredible adaptability of FR-4 laminates results from their balanced electrical, mechanical and thermal properties combined with affordable manufacturing scales. This facilitates application versatility spanning commonplace consumer gadgets to specialized industrial equipment.

Innovation continues pushing electronics into extreme environments and high frequency applications. But FR-4 epoxy glass substrates sufficiently meet most humid, pressure, temperature, and radio frequency needs with accessible fabrication techniques. This practical combination of capable performance and process ability enables ongoing ubiquity across sectors.

Environmental pressures are also driving supply chain responsibility — from chemical safety to recycling programs. While zero waste remains an ideal, existing infrastructure for accountable FR-4 material usage and recovery represents important headway.

So next time you see a PCB inside some electronics device, there’s a good chance it’s made using these versatile FR-4 copper clad laminates! The material adaptability across products we depend on every day speaks to why FR-4 continues standing out as the workhorse of the electronics manufacturing industry.

Contact Us for Application Consulting

Wondering whether rugged FR-4 can meet new application demands like aerospace-grade electrical systems? Get in touch with our engineering experts to evaluate material selections for custom reliability targets.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 FR4 fiberglass plastic