Polyether ether ketone (PEEK) plastic is an engineering thermoplastic known for its exceptional heat resistance. With a melting temperature over 330°C, PEEK offers thermal stability far beyond most other plastics.

This extreme thermal resistance makes PEEK an ideal material for components and parts exposed to high heat, including under-the-hood automotive and aerospace applications, medical sterilization equipment, and oil and gas drilling tools.

But what gives PEEK its incredible resistance to high temperatures? This article will explore the unique properties that allow PEEK to withstand extreme heat and outperform other thermoplastics.

What Makes PEEK Thermally Resistant?

PEEK owes its thermal stability to its molecular structure and chemistry. The polymer consists of an aromatic backbone molecular chain, with alternating ketone and ether functional groups.

Several factors contribute to PEEK's heat resistance:

Lack of a Glass Transition Temperature

Most thermoplastics have a defined glass transition temperature (Tg), above which the material transitions from a rigid, glassy state to a soft, rubbery state. As temperature increases above Tg, the plastic becomes less stiff and more prone to creeping under load.

PEEK does not exhibit a glass transition, maintaining its stiff, rigid chains even at high temperatures. With no glass transition phase change, PEEK shows little change in mechanical properties up to its 334°C melting point.

High Melting Point

PEEK has an extraordinarily high melting temperature of 334°C. Most commodity plastics melt or deform at temperatures below 150°C. PEEK's high melting point reflects the stability of its molecular chains and stiff backbone structure.

The aromatic rings provide thermal stability, while the ketone and ether linkages resist breakdown even at extreme temperatures. This preserves PEEK's mechanical strength well above 300°C.

Thermal Stability of Chemical Structure

PEEK's chemical composition resists oxidative degradation and decomposition at high sustained heat. The polymer retains its structural integrity and does not corrode or char.

PEEK's thermal oxidative stability gives it an advantage in environments that combine elevated temperature and contact with aggressive chemicals or radiation.

Low Coefficient of Thermal Expansion

PEEK expands very little when heated, with a coefficient of thermal expansion below 50 x 10<sup>-6</sup> m/m°C. This dimensional stability at temperature extremes prevents warping or deformation.

Components machined from PEEK hold tight tolerances without distortion, even with wide temperature fluctuations.

PEEK vs. Other Engineering Plastics

How does PEEK compare to other high-performance engineered plastics used in extreme conditions?

Nylon (PA)

Nylon has better chemical resistance than PEEK but lower temperature capabilities. The Tg of nylon is about 65°C, with melting points from 215-265°C. While strong at room temperature, nylon loses stiffness rapidly above 80°C.

Polyphenylene Sulfide (PPS)

PPS retains strength up to 190°C but has lower long-term thermal resistance than PEEK. It is more affordable but more brittle.

Polyimide (PI)

PI can withstand temperatures approaching 300°C. However, it absorbs moisture easily leading to dimensional changes. Polyimide has higher dielectric losses than PEEK.

Polyethylene Terephthalate (PET)

PET melts at 250°C and loses strength by 150°C. It decomposes faster than PEEK at high temperatures.

Polyetherimide (PEI)

With a glass transition temperature of 217°C PEI maintains properties at higher temperatures than PET or nylon. It is less expensive than PEEK but more limited in heat resistance.

Acetal (POM)

POM begins to deform above 90°C and melts at 175°C, making it unsuitable for high heat applications.

PEEK clearly outperforms other thermoplastics at extreme temperatures. The aromatic structure and ketone/ether linkages provide unparalleled thermal stability.

Applications Capitalizing on PEEK's Heat Resistance

Thanks to its uniquely high melting point and thermal stability, PEEK is widely used in applications that experience temperatures exceeding 250°C:

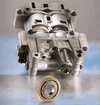

Automotive and Aerospace Components

Engine compartments, powertrain systems, exhaust components, pumps, and seals must withstand temperatures up to 350°C. PEEK's resistance to heat and chemicals makes it an ideal under-the-hood plastic.

PEEK is used for wiring insulation, gears, bushings, speakers, and other parts in close proximity to hot engines. Aerospace applications include insulation for wiring near turbines and engine mounts.

Medical Sterilization and Implants

The ability to repeatedly sterilize implants and surgical tools saves lives. PEEK's heat tolerance allows hundreds of autoclave and steam sterilization cycles.

PEEK's biocompatibility also makes it suitable for high-temperature sterilizable medical implants like replacement joints.

Oil and Gas Drilling Tools

During petroleum drilling operations, components like seals, valves, and drill bits are subjected to high heat. PEEK stands up to steam, abrasion, and corrosion in these harsh downhole environments.

PEEK's strength lets drill bits bore longer and faster, while its dimensional stability precisely controls drilling tolerances.

Electronics in Extreme Environments

PEEK's electrical insulation properties persist at elevated temperatures. It is used for connectors, switches, and wire insulation where electronics experience intermittent high heat.

Fire Protection Systems

PEEK does not burn easily and does not produce toxic fumes when exposed to fire. The UL 94 flammability standard rates PEEK as V-0, the highest rating for fire resistance.

Cooking Equipment and Smoking Pipes

For cooking tools and smoking paraphernalia designed for extended high heat, PEEK provides an inert, non-reactive surface safe for food contact.

The Future of High-Temperature Plastics

While PEEK offers unmatched performance among today's thermoplastics, researchers continue seeking ways to improve its thermal capabilities:

- Reinforced PEEK compounds with ceramic or carbon fibers boost stiffness and strength to over 300°C.

- Fillers like molybdenum disulfide improve PEEK's machinability for precision components.

- Composite blends combine PEEK with other thermoplastics for specialized high-temperature properties.

- New techniques modify PEEK's backbone structure to incrementally increase its melting point and glass transition temperature.

Other new plastics also aim to compete with PEEK in extreme environments:

- Polyphenylene sulfide (PPS) and its alloys offer higher temperature resistance focused on select properties.

- Liquid crystal polymers (LCP) provide an alternative stiff, chemically resistant structure stable to over 300°C.

- Polytetrafluoroethylene (PTFE) excels in corrosion resistance though has lower strength than PEEK.

- Polyimide (PI) possesses thermal stability near the range of PEEK but absorbs moisture easily.

While PEEK retains its dominance for universal high heat applications, tailored alternatives continue emerging for specialized uses.

Conclusion

PEEK plastic possesses unique high temperature properties unmatched by other thermoplastics. Its aromatic molecular structure, lack of a glass transition temperature phase change, and high melting point of 334°C give PEEK thermal stability to over 300°C.

Compared to plastics like nylon, acetal, PET, and PTFE, PEEK performs consistently even when exposed to extreme heat, oxidizing environments, and repeated sterilization cycles.

Thanks to properties like dimensional stability and chemical resistance at high temperatures, PEEK excels in automotive, aerospace, oil and gas, medical, and electronics applications.

Ongoing development aims to modify PEEK for even higher performance and create alternative thermoplastics with capabilities rivalling PEEK'sthermal resistance.

Understanding PEEK's superior high-temperature properties helps engineers select the right material for designs subjected to extreme heat. When performance at over 300°C is critical, PEEK provides unbeatable thermal resistance.