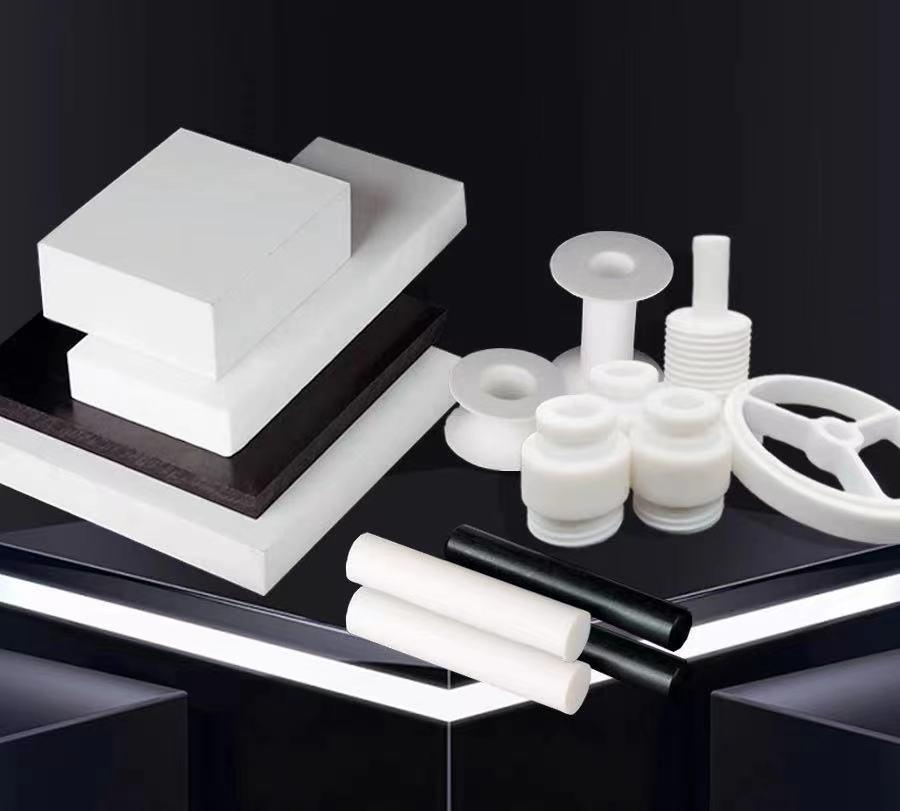

In the blog post "The Art of Engineering: CNC Machined PTFE Parts in Contemporary Design Work," we delve into the fascinating world of CNC machining and its integral role in modern product design. This comprehensive guide begins by exploring the properties and applications of PTFE, a material renowned for its versatility and performance in engineering and design. We then take a closer look at the techniques and precision involved in the CNC machining process of PTFE, revealing the meticulous craftsmanship behind each component.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 PTFE plastic

As we move forward, the post highlights innovations in design made possible by CNC machined PTFE parts, showcasing real-world examples where this technology has pushed the boundaries of what's possible in product development. A critical comparison follows, examining why PTFE stands out against other materials in the realm of CNC machining, emphasizing its unique benefits to product designers.

Finally, we gaze into the future, speculating on the evolving trends and potential new applications of CNC machined PTFE in the ever-changing landscape of contemporary design. This post is not just a technical overview but a journey through the intersection of engineering and aesthetics, demonstrating how CNC machined PTFE parts are not just components but the building blocks of innovative design.

Join us as we uncover the artistry behind the engineering, where precision meets creativity in the world of CNC machined PTFE parts.

Understanding CNC Machined PTFE Parts: Properties and Applications

In the realm of product design and engineering, the use of CNC machined PTFE parts has become increasingly prominent. This section of the blog post delves deep into the unique characteristics of PTFE (Polytetrafluoroethylene) and explores why it is a preferred material in CNC machining.

The Unique Characteristics of PTFE

PTFE, widely known by its brand name Teflon, stands out in the world of polymers due to its remarkable properties. It is renowned for its high resistance to heat, being able to withstand temperatures up to 260°C (500°F). This makes it an ideal choice for applications where thermal stability is crucial. Additionally, PTFE is chemically inert, meaning it does not react with most chemicals. This property is particularly beneficial in industries where chemical resistance is a necessity, such as in the manufacture of chemical processing equipment.

Another notable feature of PTFE is its low coefficient of friction. This characteristic ensures that parts made from PTFE exhibit minimal resistance, making them perfect for applications requiring smooth, frictionless movement. This aspect is particularly advantageous in the creation of sliding bearings and gear parts.

Why PTFE is Preferred in CNC Machining for Product Design

Versatility and Precision

When it comes to CNC machining, PTFE's versatility is unmatched. Its ease of machining allows for the creation of complex and precise parts that are essential in advanced product design. This precision is crucial in industries like aerospace, automotive, and medical devices, where exact specifications are mandatory.

Durability and Longevity

The durability of PTFE also plays a significant role in its popularity. CNC machined PTFE parts are known for their longevity, resisting wear and tear over time. This durability translates into cost-effectiveness, as products and components require less frequent replacement.

Customization and Innovation

PTFE's adaptability in CNC machining opens doors for customization and innovation in product design. Designers and engineers can experiment with various shapes and sizes, pushing the boundaries of traditional design limitations. This flexibility is essential in the development of custom parts and innovative solutions for complex design challenges.

Applications of CNC Machined PTFE Parts

CNC machined PTFE parts find applications in a myriad of industries. In the medical field, PTFE's biocompatibility makes it suitable for surgical instruments and prosthetic devices. In the electrical industry, its excellent insulating properties are utilized in wiring and electrical components. The food and beverage industry also benefits from PTFE's non-toxic and non-reactive nature, using it in equipment that requires direct contact with food.

In conclusion, the unique properties of PTFE, combined with its versatility in CNC machining, make it an invaluable material in the world of product design and engineering. Its ability to meet diverse and demanding requirements across various industries underscores its significance in modern manufacturing and design innovation.

The Process of CNC Machining PTFE: Techniques and Precision

The manufacturing world has been revolutionized by CNC (Computer Numerical Control) machining, and its application in working with PTFE (Polytetrafluoroethylene) is a testament to this advancement. This section explores the intricate technical aspects of how CNC machining is applied to PTFE, emphasizing the precision and specialized techniques involved.

Understanding CNC Machining with PTFE

The Basics of CNC Machining

CNC machining is a subtractive manufacturing process, where material is removed from a solid block (in this case, PTFE) using a variety of cutting tools to produce a part based on a CAD (Computer-Aided Design) model. With CNC machining, the level of precision achievable is significantly higher than traditional machining methods. This precision is crucial when working with PTFE, known for its application in industries where even a micron's deviation can lead to failure of a component.

Special Considerations for Machining PTFE

Machining PTFE requires a nuanced approach due to its unique properties. PTFE is softer compared to metals, which necessitates the use of specialized cutting tools and machining techniques. The tools must be sharp and precise to ensure clean cuts and avoid material deformation. Additionally, the machining parameters like speed, feed rate, and depth of cut need to be carefully optimized to prevent material warping and to maintain the integrity of the PTFE.

Advanced Techniques in CNC Machining of PTFE

Precision Engineering

The precision in CNC machining of PTFE is achieved through advanced engineering techniques. High-speed machining, combined with real-time monitoring and adjustments, ensures that the dimensions and tolerances are maintained throughout the machining process. This level of precision is essential for applications in aerospace, medical devices, and precision instrumentation.

Custom Tooling and Fixturing

Custom tooling and fixturing are often employed in the CNC machining of PTFE. Given PTFE's tendency to deform under pressure, specialized fixtures are used to hold the material firmly in place without causing damage. This custom approach allows for the production of complex and intricate parts that would be challenging to create using standard tools and fixtures.

The Role of CAD/CAM in Enhancing Precision

The integration of CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software plays a pivotal role in enhancing the precision of CNC machined PTFE parts. These software tools enable the creation of detailed and accurate designs that are directly translated into machining instructions. This seamless transition from design to production ensures that every detail of the CAD model is accurately replicated in the final part.

In summary, the process of CNC machining PTFE is a blend of art and science, requiring specialized techniques and a deep understanding of the material's properties. The precision and care taken in this process are what make CNC machined PTFE parts so valuable in critical applications across various industries. The ability to consistently produce high-quality, precise components makes CNC machining an indispensable tool in the world of modern manufacturing and design.

Innovations in Design with CNC Machined PTFE

The integration of CNC machined PTFE parts in product design has not only enhanced the functionality of numerous products but also paved the way for groundbreaking innovations. This section explores how the unique attributes of PTFE, combined with the precision of CNC machining, have led to creative and effective solutions in various fields of design.

Revolutionizing Industries with PTFE

Aerospace and Aviation

In the aerospace and aviation industry, CNC machined PTFE parts have been instrumental in developing components that can withstand extreme conditions. For instance, PTFE's resistance to high temperatures and chemical inertness makes it ideal for seals and gaskets used in aircraft engines. These components ensure reliability and safety in harsh environments, significantly enhancing aircraft performance and durability.

Medical Device Innovation

The medical sector has seen remarkable advancements with the use of CNC machined PTFE. Its biocompatibility makes it a preferred choice for various surgical tools and implants. For example, PTFE is used in creating artificial joints and heart valves, offering patients safer and more durable alternatives. The precision of CNC machining ensures these components meet the stringent requirements of medical applications.

Enhancing Everyday Products

Consumer Electronics

In the realm of consumer electronics, CNC machined PTFE parts have enabled the miniaturization of devices while improving their performance. PTFE's excellent electrical insulation properties are utilized in creating components for smartphones and laptops, allowing for sleeker designs without compromising on functionality.

Automotive Advancements

The automotive industry has also benefited from the use of CNC machined PTFE. Its low friction coefficient is perfect for creating parts like gears and bearings, which contribute to smoother vehicle operation and increased efficiency. This innovation extends the lifespan of these components, reducing maintenance needs and costs.

Pioneering Sustainable Solutions

Environmental Applications

CNC machined PTFE is playing a role in developing sustainable technologies. For instance, its chemical resistance and thermal stability are crucial in manufacturing components for solar panels and wind turbines. These applications demonstrate PTFE's potential in supporting environmentally friendly technologies.

The Future of Design with CNC Machined PTFE

Looking ahead, the possibilities for CNC machined PTFE in product design are boundless. As technology advances, we can expect to see PTFE being used in even more innovative ways, contributing to the development of products that are not only more efficient and durable but also more sustainable.

In conclusion, CNC machined PTFE has proven to be a game-changer in product design across various industries. Its unique properties, coupled with the precision of CNC machining, have led to the creation of groundbreaking products and designs. As we continue to explore the potential of this versatile material, we can expect to see a new wave of innovations that will further transform our world.