Ultra High Molecular Weight Polyethylene (UHMWPE) has steadily gained traction in modern manufacturing industries, thanks to its unparalleled properties that lend superior performance, longevity and customization potential. UHMWPE sheets in particular offer exceptional strength, abrasion resistance and chemical resistance, making them suitable for numerous applications from food processing equipment to heavy-duty machine parts.

This article will provide an in-depth look at UHMWPE sheets – from understanding their unique properties to exploring common and innovative industrial applications across manufacturing sectors. We’ll also discuss sourcing considerations when choosing UHMWPE sheet suppliers to find products capable of meeting specialized performance requirements. Let’s get started.

Understanding UHMWPE Sheets

What is UHMWPE Material?

UHMWPE, short for Ultra High Molecular Weight Polyethylene, is a thermoplastic polymer known for having extremely long chains of polyethylene oriented in the same direction. This alignment gives rise to exceptional tensile strength, rigidity and abrasion resistance properties.

UHMWPE has a molecular weight numbering in the millions, hence the name. It also stands apart for being highly chemically inert and safe for food contact.

UHMWPE Sheet Properties

Owing to its molecular arrangement, UHMWPE sheets offer the following noteworthy performance properties:

- Extreme tensile strength

- Resistance to corrosive chemicals and stress cracking

- Low moisture absorption and permeation

- Resistance to abrasive wear and friction

- Impact strength and ductility

- Food contact compliant

UHMWPE Manufacturing Process

UHMWPE sheets are produced through a process called compression molding of UHMWPE resin under high heat and pressure. This aligns the molecular chains evenly across the sheet thickness, conferring optimal directional properties.

Adding fillers like carbon fibers during processing can enhance certain attributes like conductance for specialized applications.

The Unique Properties of UHMWPE Sheets

UHMWPE Sheet Durability and Strength

A prime advantage of UHMWPE sheets is exceptional durability and load-bearing capacity. UHMWPE exhibits yield strength 2-3 times higher than regular polyethylene. The highly oriented molecular chains distribute force evenly, preventing premature cracking or crumbling under strain.

This allows UHMWPE sheets to withstand up to 1,000 psi of continuous stress in demanding environments. UHWMPE machine parts thus demonstrate above-average service life over metal components.

UHMWPE Sheet Flexibility and Resistance

Despite its heavy-duty strength, UHMWPE offers sufficient flexibility to withstand repeated bending and deformations from use. This includes twist, tensile and hinge movements over time without rupture.

Moreover, the chemical inertness of UHWMPE sheets translates into multi-faceted environmental resistance:

- Abrasion: Surface stands up to rubbing, scuffing, and erosion

- Corrosion: No oxidation or effects from acids, bases, salts

- Chemicals: Highly non-reactive to solvents, oils and cleaning fluids

- Impact: Absorbs vibrations, blows and mechanical shocks

UHMWPE Sheet Versatility

Owing to this rare combination of strength, flexibility and resistance, UHMWPE sheets provide versatile utility across manufacturing applications - from parts subject to daily wear-and-tear to custom equipment for hazardous chemical processing.

Engineers increasingly prefer this advanced polymer in replace of steel, alloy or rubber components to improve product performance.

Industrial Applications of UHMWPE Sheets

UHMWPE Sheets in Manufacturing

Leading manufacturers utilize custom UHMWPE sheets or finished parts to enhance equipment reliability and output:

- Food Processing: UHMWPE-lined mixing arms, conveyor belt guides, and macerator funnels optimize hygiene and minimize cross-contamination.

- Packaging: Anti-static UHMWPE sheets feed bulk material steadily into fill lines without sticking or slowdown.

- Robotics: Replace traditional metals with lightweight UHMWPE links and actuators for faster automated processes.

- Pulleys: Sprockets and bearings made of UHMWPE withstand heavy loads and last longer before needing replacement.

Custom UHMWPE Sheets for Specialized Needs

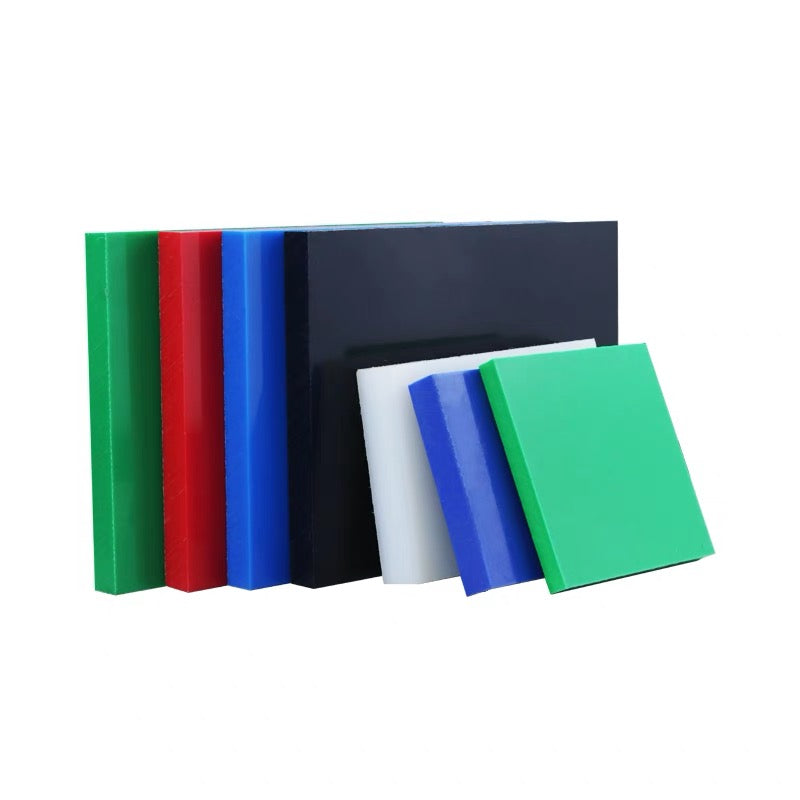

Reputable UHMWPE sheet manufacturers offer a range of grades, thicknesses and custom fabrications to meet specialized requirements:

- Standard, static-dissipative, conductive, and detectable blue UHMWPE grades.

- Sheets from 0.5mm to 100mm thickness for lightweight to heavy-duty applications.

- Precision-machined fins, rollers, bin covers, conveyor guards etc.

This enables clients to replace parts once deemed impossible to produce in plastic.

UHMWPE Sheet Applications in Robotics and Aerospace

The uncommon strength and electrical properties of certain UHMWPE sheet products have unlocked innovative applications in high-tech fields:

- Conductive UHMWPE sheets embedded with sensor arrays accurately trace robotic arm and gripper movements.

- Thin detectable blue UHMWPE sheets prevent foreign object debris (FOD) around aircraft.

- Lightweight UHMWPE padding lines high-G force fighter pilot helmets.

Such niche applications highlight the possibilities of this adaptable and ever-evolving material.

Choosing the Right UHMWPE Sheets

UHMWPE Sheet Suppliers and Quality

With growing demand for UHMWPE parts across industries, many suppliers now offer stock and custom sheet materials:

- Seek established manufacturers with in-house molding capabilities.

- Evaluate quality control and compliance certifications.

- Compare UHMWPE sheet pricing based on thickness, size, fabrication costs etc.

This helps avoid quality inconsistencies or hidden fees.

How to Cut UHMWPE Sheet

While UHMWPE sheets lend well to machining, clients should adhere to a few guidelines:

- Use sharp, high-RPM blades for tear-free edges.

- Account for 1-2% thickness shrinkage during precision cutting.

- Apply gentle settings and adequate cooling fluid to avoid heat damage.

Reputable suppliers can provide cutting recommendations specific to your project.

UHMWPE sheets continue to widen the horizons for manufacturing applications where high impact, low friction, chemical resistance and food compliance are vital. As materials science unlocks new grades and production methods, engineers across sectors should continually evaluate UHMWPE sheets as a solution to their most pressing equipment challenges for reliability and output. By selecting quality-assured UHMWPE sheet stock and fabrication partners, the next generation of improved industrial machinery is sure to take shape.

To explore how specialty UHMWPE sheets can optimize your manufacturing operations, please contact our team of polymer experts at www.beeplastic.com. Or browse our online catalog for off-the-shelf and custom UHMWPE sheets purpose-built for your needs.