In my latest blog post, "Innovative Uses of Bakelite Sheets: From Electronics to Art," I dive deep into the multifaceted world of Bakelite and its modern applications. This versatile material, known for its durability and heat resistance, is making waves in various industries today.

Bakelite in High-Frequency Electronics

Learn how Bakelite sheets are revolutionizing high-frequency electronics with their excellent insulation properties, providing cost-effective solutions for RF insulators and specialized electronic circuits.

Heat Management Solutions

Discover the innovative role of Bakelite in managing heat within electronic devices. Its thermal stability makes it perfect for heat sinks and thermal insulators, crucial for the longevity and reliability of power electronics.

Advanced Composite Materials

Explore the creation of advanced composites by combining Bakelite with materials like carbon fibers or metals. These composites enhance mechanical strength and electrical properties, making them ideal for aerospace and automotive electronics.

Sustainable Electronic Components

Find out how Bakelite promotes sustainability in electronics manufacturing. Its durability reduces environmental impact, making it a preferred choice for components in renewable energy systems like solar panels and wind turbines.

Artistic and Decorative Applications

Uncover the artistic potential of Bakelite sheets. From jewelry to decorative objects, this material's unique aesthetic appeal and ability to be intricately carved make it a favorite among artists and crafters.

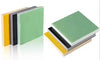

Architectural and Interior Design Uses

Discover how Bakelite sheets are used in architectural and interior design for countertops, wall tiles, partitions, and decorative accents, thanks to their sleek appearance and heat resistance.

Industrial and Mechanical Applications

Learn about Bakelite's role in industrial and mechanical products such as gears, bearings, housings, and fittings. Its properties like reducing friction and maintaining dimensional stability under high loads make it indispensable in these fields.

Join me as I explore the versatility and innovation behind Bakelite sheets and their growing importance across various industries. Whether you're in electronics, design, or manufacturing, you'll find valuable insights on how to leverage this incredible material.

Bakelite in High-Frequency Electronics

The Role of Bakelite Sheets in High-Frequency Electronics

Bakelite sheets are essential in high-frequency electronics due to their outstanding insulation properties and cost-effectiveness. These properties make Bakelite an ideal material for components such as RF insulators and specialized electronic circuits.

Applications in RF Insulators

RF insulators are critical in maintaining the efficiency and performance of high-frequency electronic devices. Bakelite sheets provide excellent electrical insulation, ensuring that signals remain uninterrupted and free from interference. Their stability under varying environmental conditions makes them a reliable choice for such applications.

Specialized Electronic Circuits

In specialized electronic circuits, Bakelite plays a pivotal role. Its low moisture absorption is crucial in preventing short circuits and maintaining the integrity of electronic components. This characteristic ensures that Bakelite-based components perform consistently even in humid conditions, which is vital for maintaining the reliability of high-frequency electronics.

Cost-Effectiveness of Bakelite

One of the major advantages of using Bakelite sheets in high-frequency electronics is their cost-effectiveness. While newer materials are available, Bakelite offers a balance of performance and affordability. This makes it a preferred choice for manufacturers looking to optimize costs without compromising on quality.

Stability and Durability

Bakelite's stability under various environmental conditions is another significant benefit. It does not deform or degrade easily, which is essential for components exposed to high frequencies and varying temperatures. This durability ensures a longer lifespan for electronic components, reducing the need for frequent replacements and maintenance.

Advancements in Material Science

Recent advancements in material science have further enhanced the properties of Bakelite. Researchers are continuously exploring ways to improve its thermal stability and electrical insulation, making it even more suitable for high-frequency applications. These innovations are expanding the potential uses of Bakelite in the electronics industry.

Environmental Considerations

In addition to its technical advantages, Bakelite is also considered a more environmentally friendly option compared to some modern plastics. Its durability reduces the frequency of replacements, leading to less electronic waste. As industries move towards sustainable practices, Bakelite's long lifespan and reliability make it an attractive choice for eco-conscious manufacturers.

Conclusion

The use of Bakelite sheets in high-frequency electronics highlights their versatility and reliability. From RF insulators to specialized electronic circuits, Bakelite's properties make it an indispensable material in the electronics industry. Its cost-effectiveness, stability, and advancements in material science ensure that Bakelite remains a vital component in modern high-frequency electronics.

By incorporating Bakelite into high-frequency electronics, manufacturers can achieve a balance of performance, durability, and environmental responsibility, making it a smart choice for the future of electronic device design and production.

Heat Management Solutions in Electronics

The Role of Bakelite in Heat Management

Bakelite plays a pivotal role in managing heat within electronic devices. Its exceptional thermal stability and resistance to degradation make it an ideal material for heat sinks and thermal insulators in power electronics. These properties ensure that electronic components remain cool and function optimally, even under high thermal loads.

Thermal Stability of Bakelite

The thermal stability of Bakelite is one of its most significant advantages. Unlike many other materials, Bakelite can withstand high temperatures without losing its structural integrity. This makes it an excellent choice for components that are exposed to continuous heat, such as power transistors and voltage regulators. By maintaining its form and function under extreme conditions, Bakelite helps prevent overheating and prolongs the lifespan of electronic devices.

Resistance to Degradation

Bakelite's resistance to degradation is another critical feature that enhances its suitability for heat management in electronics. It does not easily degrade when exposed to high temperatures, chemicals, or moisture, which are common in electronic environments. This resistance ensures that Bakelite components remain reliable and efficient over time, reducing the need for frequent replacements and maintenance.

Applications in Heat Sinks

Heat sinks are essential components in electronic devices, designed to dissipate heat away from sensitive parts. Bakelite is used in heat sinks due to its ability to conduct heat efficiently while remaining electrically insulating. This combination ensures that heat is effectively managed without causing electrical interference, which is crucial in maintaining the performance and safety of electronic devices.

Thermal Insulators in Power Electronics

In power electronics, managing heat is vital for device longevity and reliability. Bakelite serves as an excellent thermal insulator, preventing heat from spreading to other components and maintaining optimal operating temperatures. Its use in components like transformers, inductors, and capacitors highlights its importance in protecting and enhancing the efficiency of power electronic systems.

Durability and Longevity

The durability of Bakelite further contributes to its effectiveness in heat management. Its robust nature ensures that it can endure harsh conditions without compromising its insulating properties. This durability not only enhances the performance of electronic devices but also contributes to sustainability by reducing the frequency of replacements and associated waste.

Innovations in Material Science

Recent advancements in material science have led to the development of enhanced Bakelite composites. These innovations improve the thermal conductivity and mechanical strength of Bakelite, making it even more effective in managing heat in advanced electronic applications. By incorporating these composites, manufacturers can achieve better thermal management and overall device performance.

Environmental Considerations

In addition to its technical benefits, Bakelite is also considered a more sustainable option compared to some modern plastics. Its long lifespan reduces electronic waste, aligning with the growing emphasis on environmental responsibility in manufacturing. This makes Bakelite an attractive choice for eco-conscious manufacturers looking to improve the thermal management of their electronic devices.

Bakelite continues to prove its value in the electronics industry, especially in managing heat within devices. Its unique combination of thermal stability, resistance to degradation, and durability makes it a preferred material for heat sinks and thermal insulators in power electronics.

Advanced Composite Materials

Combining Bakelite with Carbon Fibers

Bakelite, when combined with carbon fibers, creates advanced composite materials that offer enhanced mechanical strength and improved electrical characteristics. These composites leverage the inherent properties of both materials to produce components that are not only robust but also lightweight and electrically insulating. Carbon fibers provide high tensile strength and stiffness, which complement Bakelite's thermal stability and durability. This combination is particularly useful in applications where high performance and reliability are crucial.

Enhancing Mechanical Strength

The incorporation of carbon fibers into Bakelite composites significantly enhances their mechanical properties. Carbon fibers are known for their exceptional strength-to-weight ratio, making the resulting composites ideal for demanding environments. These advanced composites can withstand high mechanical loads without deforming or breaking, making them suitable for use in automotive electronics and aerospace applications. In these industries, components must endure extreme conditions, such as high stress, vibration, and temperature fluctuations.

Improving Electrical Characteristics

In addition to mechanical strength, Bakelite-carbon fiber composites also offer improved electrical characteristics. The non-conductive nature of Bakelite ensures excellent electrical insulation, while the structural integrity provided by carbon fibers ensures that the components remain stable and reliable. This makes these composites ideal for use in high-performance electronic circuits and components where electrical insulation is critical. Applications include printed circuit boards (PCBs), insulators, and electronic housings that need to operate reliably in harsh conditions.

Applications in Aerospace Electronics

Bakelite composites are extensively used in the aerospace industry due to their ability to withstand high temperatures and mechanical stress. Components made from these composites are used in various parts of aircraft, including avionics and sensor housings. The lightweight nature of carbon fibers helps reduce the overall weight of the aircraft, contributing to better fuel efficiency and performance. Moreover, the thermal stability and durability of Bakelite ensure that these components can endure the rigorous demands of aerospace environments.

Applications in Automotive Electronics

In the automotive industry, Bakelite-carbon fiber composites are used in the production of high-performance electronic components. These include ignition systems, control units, and sensor housings. The combination of mechanical strength and electrical insulation provided by these composites ensures that automotive electronics can operate reliably under the hood, where they are exposed to high temperatures and mechanical vibrations. This enhances the safety and efficiency of modern vehicles, making them more reliable and longer-lasting.

Integration with Metallic Components

Bakelite can also be combined with metallic components to create composites with unique properties. By integrating metals like aluminum or copper, the resulting Bakelite-metal composites offer enhanced thermal conductivity while maintaining good electrical insulation. These composites are useful in applications that require efficient heat dissipation, such as power electronics and thermal management systems. The metallic components help to spread heat away from sensitive areas, while the Bakelite ensures that electrical insulation is maintained.

Future Innovations in Composite Materials

Ongoing research and development in material science are continually pushing the boundaries of Bakelite composites. Innovations aim to further enhance the properties of these materials, making them even more suitable for advanced electronic applications. This includes the development of nano-composites and the use of bio-based materials to improve sustainability. These advancements are expected to open new possibilities for Bakelite composites in various high-tech industries, ensuring their relevance and importance in the future of electronics and beyond.

By integrating Bakelite with advanced materials like carbon fibers and metals, manufacturers can produce components that meet the stringent requirements of modern electronic and industrial applications. The result is a range of high-performance, durable, and reliable materials that continue to drive innovation in aerospace, automotive, and beyond.

Sustainable Electronic Components

Promoting Sustainability in Electronics Manufacturing with Bakelite

Bakelite plays a significant role in promoting sustainability within the electronics manufacturing sector. Its inherent durability and long lifespan make it an eco-friendly choice compared to other materials. By using Bakelite, manufacturers can create products that last longer, reducing the need for frequent replacements and minimizing electronic waste. This reduction in waste contributes to a lower environmental footprint, aligning with the growing emphasis on sustainability in manufacturing.

Durability Reduces Environmental Impact

One of the standout features of Bakelite is its exceptional durability. Unlike many modern plastics, Bakelite does not degrade easily over time. This durability means that components made from Bakelite can withstand harsh conditions and remain functional for extended periods. In electronic devices, this translates to a longer lifespan, reducing the frequency of replacements. Fewer replacements mean less waste, contributing to a more sustainable approach to electronics manufacturing. By extending the life of electronic components, Bakelite helps reduce the overall environmental impact of production and disposal.

Bakelite in Renewable Energy Systems

Bakelite's potential extends beyond traditional electronics into the realm of renewable energy systems. Its excellent thermal stability and electrical insulation properties make it an ideal material for components in solar panels and wind turbines. In solar panels, Bakelite can be used in various insulating parts to protect electrical components from heat and environmental exposure. Its ability to withstand high temperatures without degrading ensures that solar panels remain efficient and reliable over their operational lifespan.

Components in Solar Panels

Solar panels require materials that can endure constant exposure to sunlight and fluctuating temperatures. Bakelite is an excellent choice for insulating components within solar panels due to its heat resistance and durability. By using Bakelite, manufacturers can ensure that these critical parts do not degrade quickly, thereby maintaining the efficiency and effectiveness of the solar panels. This durability not only enhances the performance of renewable energy systems but also contributes to their overall sustainability by reducing the need for frequent maintenance and replacements.

Applications in Wind Turbines

In wind turbines, Bakelite is used for similar purposes. Its electrical insulating properties are crucial for components that must resist electrical interference and heat generated by mechanical operations. Bakelite's robustness ensures that these components remain operational under the stress of continuous movement and exposure to the elements. By integrating Bakelite into wind turbine designs, manufacturers can create more durable and reliable systems that contribute to the long-term viability of renewable energy.

Environmental Benefits of Using Bakelite

The environmental benefits of using Bakelite are manifold. Its long lifespan means less frequent replacements, which translates to reduced waste. Furthermore, the manufacturing process of Bakelite, while involving synthetic materials, results in a product that does not easily break down into microplastics. This characteristic is significant in the context of reducing pollution and maintaining cleaner ecosystems. Additionally, ongoing research into bio-based Bakelite and other sustainable innovations aims to further reduce its environmental footprint, making it an even more attractive option for eco-conscious manufacturers.

Advancements in Sustainable Bakelite

Recent advancements in material science are making Bakelite even more sustainable. Researchers are developing bio-based Bakelite by using renewable resources for its production, reducing reliance on fossil fuels. These innovations not only lower the environmental impact of Bakelite's production but also enhance its properties, making it more versatile for a wider range of applications. By adopting these advancements, manufacturers can contribute to a more sustainable future while benefiting from the robust and reliable nature of Bakelite.

Bakelite's role in promoting sustainability in electronics manufacturing is clear. Its durability, thermal stability, and potential applications in renewable energy systems make it a valuable material for creating long-lasting, eco-friendly electronic components. As industries continue to prioritize environmental responsibility, Bakelite's contributions to sustainability will only grow more significant.

Bakelite in Artistic and Decorative Applications

The Unique Aesthetic Appeal of Bakelite

Bakelite has a distinct and timeless aesthetic that has captured the attention of artists and designers for decades. Its rich colors, glossy finish, and ability to be intricately carved and polished make it a favorite material for creating artistic and decorative objects. Unlike many modern plastics, Bakelite has a vintage charm that adds a touch of elegance and nostalgia to any piece. This unique appeal has ensured Bakelite's place in the world of art and craft, where it continues to inspire creativity and innovation.

Bakelite in Jewelry

One of the most popular artistic applications of Bakelite sheets is in the creation of jewelry. From the early 20th century to the present, Bakelite has been used to craft a wide range of jewelry items, including bracelets, bangles, earrings, and rings. The material's ability to be easily carved and polished allows artisans to create intricate and detailed designs that are both beautiful and durable. Bakelite jewelry is prized for its vibrant colors and smooth finish, making it a standout choice for those looking to add a retro touch to their accessory collection.

Decorative Objects and Retro-Style Items

Bakelite is also widely used in making decorative objects and retro-style items. Its versatility allows it to be shaped into a variety of forms, from small figurines and ornaments to larger home decor pieces like vases and picture frames. The vintage aesthetic of Bakelite adds a unique charm to these objects, making them popular among collectors and interior designers. The material's durability ensures that these decorative items maintain their appearance over time, preserving their beauty and value for years to come.

Intricate Carving and Polishing

The ability to intricately carve and polish Bakelite is one of its most appealing characteristics. Artists and crafters appreciate how Bakelite can be worked into fine details, allowing for the creation of complex patterns and shapes. This makes Bakelite an ideal material for custom, one-of-a-kind pieces that require precision and attention to detail. The smooth, polished surface of Bakelite also enhances its visual appeal, adding a professional finish to any artistic creation.

Popularity Among Artists and Crafters

Bakelite remains a popular choice among artists and crafters due to its unique properties and aesthetic qualities. It is celebrated for its ease of use, allowing creators to experiment with various techniques and styles. Whether used in jewelry making, decorative arts, or crafting retro-style items, Bakelite offers endless possibilities for artistic expression. Its enduring popularity is a testament to its versatility and the timeless appeal of its distinctive look.

Modern Innovations and Uses

While Bakelite is often associated with vintage and retro styles, modern artists and designers continue to find new and innovative ways to incorporate it into their work. Advances in material science have expanded the potential applications of Bakelite, allowing it to be used in contemporary designs that blend old-world charm with modern aesthetics. This fusion of past and present ensures that Bakelite remains relevant and continues to inspire new generations of artists and crafters.

Bakelite's role in artistic and decorative applications highlights its versatility and enduring appeal. Its unique combination of aesthetic qualities, durability, and workability makes it a valuable material for a wide range of creative projects. Whether used to craft stunning jewelry, elegant decorative objects, or innovative modern designs, Bakelite continues to be a source of inspiration and beauty in the world of art and craft.

Architectural and Interior Design Uses

Bakelite in Countertops

Bakelite sheets are widely used in countertops due to their durability and heat resistance. These properties make Bakelite an ideal material for kitchen and bathroom countertops where surfaces are frequently exposed to high temperatures from cooking appliances or hot water. The sleek, polished appearance of Bakelite adds a touch of modernity and elegance to any space, making it a favored choice among interior designers.

Wall Tiles and Partitions

In architectural design, Bakelite wall tiles and partitions offer both aesthetic appeal and practical benefits. The material's heat resistance ensures that it can withstand the environmental stresses found in both residential and commercial settings. Additionally, Bakelite's durability means that these tiles and partitions are less prone to damage and can maintain their appearance over time. The versatility of Bakelite allows it to be used in a variety of colors and finishes, providing designers with the flexibility to create unique and personalized spaces.

Decorative Accents

Decorative accents made from Bakelite add a distinctive touch to both interior and architectural designs. Items such as molding, trim, and decorative panels benefit from Bakelite’s ability to be intricately carved and polished. These accents can enhance the visual appeal of a room by adding intricate details and a polished look. Bakelite's ability to hold its shape and finish makes it an excellent choice for detailed work that requires a high level of craftsmanship.

Durability and Heat Resistance

The durability of Bakelite is one of its most significant advantages in architectural and interior design. Unlike many modern materials, Bakelite can withstand significant wear and tear without losing its structural integrity. This makes it ideal for high-traffic areas where surfaces are subjected to frequent use and potential damage. Additionally, Bakelite's heat resistance is crucial in environments where it might be exposed to high temperatures, such as near stoves or heating systems. These properties ensure that Bakelite components remain functional and aesthetically pleasing for many years.

Sleek Appearance

Bakelite’s sleek appearance is another reason it is favored in design applications. Its smooth, glossy finish can be easily maintained, making it an attractive option for surfaces that need to look clean and polished. The material's ability to be produced in a variety of colors and finishes means that it can be tailored to suit different design aesthetics, from classic to contemporary. This versatility allows designers to use Bakelite in a wide range of applications, creating cohesive and visually appealing spaces.

Sustainable Design Choices

Using Bakelite in architectural and interior design also supports sustainable practices. The material's long lifespan reduces the need for frequent replacements, minimizing waste and the environmental impact associated with the production and disposal of building materials. Additionally, ongoing research into more sustainable production methods for Bakelite, such as using bio-based phenols, is making it an even more eco-friendly option. This aligns with the growing emphasis on sustainability in architecture and design.

Versatility in Application

The versatility of Bakelite in architectural and interior design cannot be overstated. Its ability to be molded into various shapes and sizes makes it suitable for a wide range of applications, from large structural elements to small decorative details. This flexibility allows designers to experiment and innovate, using Bakelite to achieve unique and customized design solutions. Whether used in traditional or modern settings, Bakelite offers the reliability and aesthetic appeal needed to enhance any architectural or interior design project.

By leveraging the unique properties of Bakelite, architects and interior designers can create spaces that are not only beautiful and functional but also durable and sustainable. The material’s durability, heat resistance, and sleek appearance make it an excellent choice for various design applications, ensuring that it remains a valued material in the design industry.

Industrial and Mechanical Applications

Bakelite in Gears and Bearings

Bakelite is widely used in the production of gears and bearings due to its excellent mechanical properties. These components benefit from Bakelite’s ability to reduce friction and maintain dimensional stability under high loads. In industrial machinery, where precision and reliability are crucial, Bakelite gears and bearings ensure smooth operation and long-lasting performance. The low friction coefficient of Bakelite minimizes wear and tear, extending the lifespan of the machinery and reducing maintenance costs.

Housings and Enclosures

Bakelite housings and enclosures are essential in protecting sensitive mechanical and electronic components from environmental factors. The material's resistance to chemicals and heat makes it ideal for use in harsh industrial environments. Bakelite can withstand exposure to various chemicals and high temperatures without degrading, ensuring that the components inside remain safe and functional. This durability is particularly important in industries such as automotive and aerospace, where components are exposed to extreme conditions.

Fittings and Connectors

In the realm of fittings and connectors, Bakelite excels due to its dimensional stability and ease of machining. These properties make Bakelite an ideal material for creating precise and reliable fittings that are essential in maintaining the integrity of mechanical systems. Bakelite connectors are commonly used in electrical applications due to their excellent insulating properties, ensuring safe and efficient connections in complex industrial setups.

Reducing Friction and Wear

One of the key advantages of using Bakelite in industrial and mechanical applications is its ability to reduce friction. This property is crucial in components such as bearings and gears, where reducing friction can significantly enhance performance and efficiency. By minimizing friction, Bakelite helps prevent excessive wear and tear, reducing the need for frequent replacements and maintenance. This not only extends the life of the machinery but also lowers operational costs.

Maintaining Dimensional Stability

Bakelite’s dimensional stability under high loads and varying temperatures is another critical factor that makes it suitable for industrial use. Components made from Bakelite do not easily deform or change shape, ensuring consistent performance even under stress. This stability is particularly valuable in precision machinery where even slight deviations can lead to malfunctions or inefficiencies. Bakelite’s ability to maintain its shape and dimensions under pressure makes it a reliable choice for high-stress applications.

Chemical and Heat Resistance

Bakelite’s resistance to chemicals and heat is essential for many industrial applications. In environments where components are exposed to harsh chemicals, Bakelite remains unaffected, ensuring long-term durability and reliability. Its heat resistance makes it suitable for use in high-temperature applications, such as in the automotive and aerospace industries, where components must endure extreme heat without compromising their structural integrity. This resistance to both chemicals and heat ensures that Bakelite components perform consistently and reliably in demanding environments.

Applications in the Automotive Industry

In the automotive industry, Bakelite is used to manufacture various components, including ignition systems, brake components, and dashboard panels. The material's ability to withstand high temperatures and its insulating properties make it ideal for automotive applications. Bakelite’s durability ensures that these components can endure the rigors of daily use, contributing to the overall reliability and safety of vehicles.

Applications in Aerospace

The aerospace industry also benefits from Bakelite's unique properties. Components made from Bakelite, such as insulators, brackets, and housings, are used in aircraft and spacecraft to ensure reliable performance under extreme conditions. The material’s ability to maintain its properties in high-stress environments makes it an essential component in the design and manufacturing of aerospace systems.

By leveraging Bakelite’s exceptional properties, industries can enhance the performance, durability, and reliability of their mechanical and industrial products. The material’s ability to reduce friction, maintain dimensional stability, and resist chemicals and heat makes it a versatile and valuable choice for a wide range of applications.

Frequently Asked Questions (FAQs) About Bakelite and BeePlastics Customization

1. What is Bakelite, and what are its primary uses?

Bakelite is one of the first synthetic plastics, developed by Dr. Leo Baekeland in 1907. It is known for its excellent electrical insulation properties, heat resistance, and durability. Bakelite is commonly used in electrical insulators, automotive components, jewelry, decorative items, and various industrial applications.

2. What makes Bakelite suitable for high-frequency electronics?

Bakelite is ideal for high-frequency electronics due to its excellent insulation properties and low moisture absorption. These characteristics prevent electrical interference and short circuits, making Bakelite a reliable material for components like RF insulators and specialized electronic circuits.

3. How does Bakelite contribute to sustainability in electronics manufacturing?

Bakelite promotes sustainability by offering durability and a long lifespan, which reduce the need for frequent replacements. Its use in renewable energy systems, such as components in solar panels and wind turbines, further supports sustainability by enhancing the efficiency and longevity of these systems.

4. Can Bakelite be customized for specific industrial applications?

Yes, Bakelite can be customized for various industrial applications. At BeePlastics, we undertake any form of customization, including sample and batch customization. We accept a variety of file formats, including PDF and CAD, to meet your specific design requirements.

5. What are the advantages of using Bakelite in automotive and aerospace industries?

In the automotive industry, Bakelite is used for ignition systems, brake components, and dashboard panels due to its heat resistance and electrical insulating properties. In the aerospace industry, Bakelite components such as insulators and housings offer reliability and durability under extreme conditions, making them essential for aircraft and spacecraft.

6. Does BeePlastics have a minimum order quantity (MOQ) for custom Bakelite products?

No, at BeePlastics, there is no minimum order quantity (MOQ) for custom Bakelite products. We cater to projects of all sizes, whether you need a single prototype or a full-scale production run.

7. How does BeePlastics manage the production cycle for custom orders?

The production cycle at BeePlastics is tailored according to the amount of orders and the complexity of the process. We ensure real-time communication with our clients regarding the production progress to keep them informed at every stage.

8. Can BeePlastics provide samples for custom Bakelite products?

Yes, BeePlastics supports the provision of samples for custom Bakelite products. The sample itself is free of charge, but the customer is responsible for the shipping costs. This allows clients to evaluate the product before committing to larger orders.

9. What types of file formats does BeePlastics accept for customization orders?

BeePlastics accepts a variety of file formats for customization orders, including PDF and CAD files. This flexibility ensures that we can accommodate different design specifications and make the customization process as smooth as possible for our clients.

10. What are the main properties of Bakelite that make it ideal for industrial and mechanical applications?

Bakelite is ideal for industrial and mechanical applications due to its properties such as reducing friction, maintaining dimensional stability under high loads, and resistance to chemicals and heat. These characteristics make it suitable for producing gears, bearings, housings, and fittings that need to perform reliably under demanding conditions.

By addressing these common questions, you can better understand the versatility and benefits of Bakelite and the comprehensive customization services offered by BeePlastics. Whether you are involved in electronics, automotive, aerospace, or industrial manufacturing, Bakelite offers reliable solutions tailored to meet your specific needs.

In exploring the innovative and versatile uses of Bakelite, we see how this remarkable material continues to be a cornerstone in various industries. From its crucial role in high-frequency electronics and heat management solutions to its application in advanced composites and sustainable energy systems, Bakelite proves to be indispensable. Its aesthetic appeal and workability make it a favorite in artistic and decorative applications, while its durability and resilience ensure its prominence in architectural design and industrial mechanics. The customization capabilities at BeePlastics further enhance the value of Bakelite, offering tailored solutions that meet diverse needs without compromising on quality or sustainability. Whether you are looking to enhance your electronics, create beautiful decorative pieces, or build robust industrial components, Bakelite offers the reliability and versatility needed to achieve your goals.

Get Customized Bakelite Solutions Now!

Let us help you bring your vision to life with our expert Bakelite customization services. Complete the contact form at the bottom of this page to get started, and don't forget to check out our detailed Bakelite product options at BeePlastics.