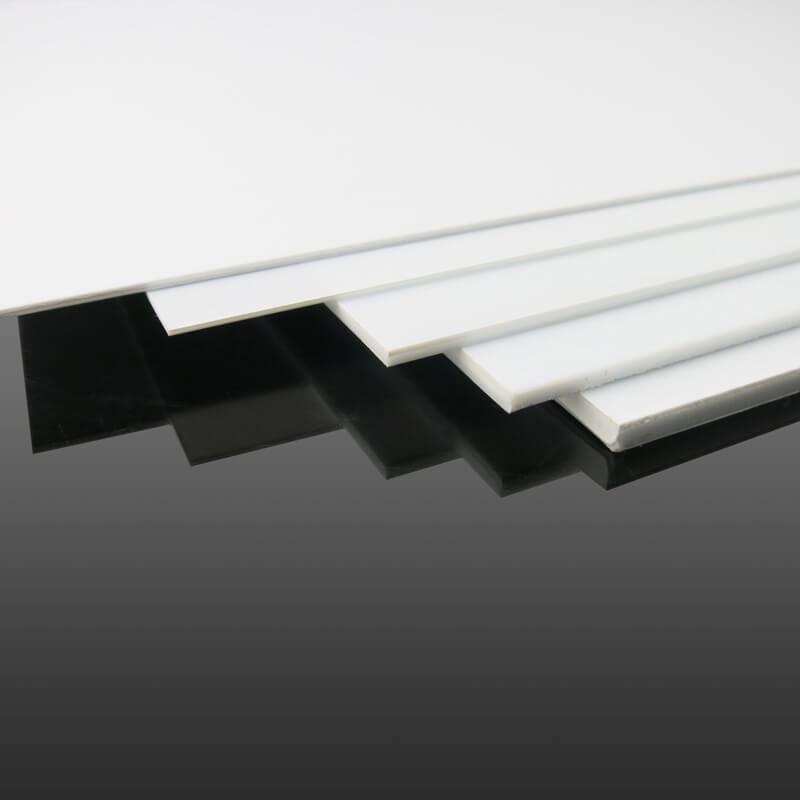

Acrylonitrile Butadiene Styrene (ABS) plastic sheets have become a popular material across various industries like manufacturing, machining, and thermoforming. From CNC routing, laser cutting, signboards to cabinetry, ABS offers an ideal balance of strength, lightweight, and formability.

However, one of the biggest considerations when working with ABS sheets is determining the right thickness for your specific application. The thickness of the ABS sheet greatly impacts the mechanical properties, workability, and cost. This comprehensive guide will walk you through everything you need to know to pick the ideal ABS sheet thickness.

Factors That Determine Proper ABS Sheet Thickness

Choosing the appropriate ABS sheet thickness involves evaluating a few key factors:

Desired Strength and Rigidity

Thicker ABS sheets tend to provide greater strength and rigidity. For applications requiring durability - like structural components or high-wear parts, a thicker 5-10mm sheet is recommended. Thinner 1-2mm sheets are more flexible and pliable.

Application and End-Use

Consider the end-use and operating conditions to choose a thickness that can withstand expected impacts, stresses, and wear & tear. For outdoor usage, thicker sheets are more weather-resistant.

Weight Restrictions

The density of ABS is around 1.07 g/cm3. Evaluate any weight limitations as thicker sheets will be heavier. For lightweight parts, aim for an ABS thickness around 1-3mm.

Machining Factors

Thicker ABS sheets are easier to machine and route without warping, while thinner sheets 1-2mm can warp more easily during laser cutting.

Cost Implications

Increasing the ABS sheet thickness also increases material costs. Evaluate your budget constraints and part quantities needed when selecting the thickness.

ABS Sheet Thickness Guide by Application

The ideal ABS sheet thickness for your project depends heavily on the application. Here are some common application-based ABS thickness recommendations:

ABS Sheet Thickness for Laser Cutting

For laser cutting applications, ABS sheets between 1-3mm are recommended. At this thinner gauge, the laser can cut through the ABS with precision and clean edges without overheating the material. Excessive heat from lasers can melt and warp thicker ABS sheets.

ABS Sheet Thickness for CNC Routing

With CNC routing, thicker ABS sheets around 3-5mm are ideal as they are rigid enough to withstand the routing process without excessive vibration or deflection. Thinner sheets below 3mm are prone to warping under the forces involved in CNC machining. The thicker material also helps minimize chipping at the routed edges.

ABS Sheet Thickness for Furniture Making

When constructing furniture or cabinetry using ABS sheets, the standard thickness is between 3-5mm. This provides the right balance of lightweight strength and structure for furniture applications. Specific components like shelves, sides or drawer fronts can use up to 10mm for enhanced sturdiness.

ABS Sheet Thickness for Model Making/Prototyping

For scale models, architectural models, concept prototypes and other design or hobby applications, opt for ABS sheets between 2-3mm thickness. This allows creating fine details and shaping without being too fragile.

ABS Sheet Thickness for Display Signs

Outdoor signs and displays exposed to weather require durable ABS sheets around 5-10mm thick. This gives the signs structural rigidity and resistance against wind, rain, and sunlight. Indoor displays may only need 2-3mm ABS sheets.

How Sheet Thickness Impacts ABS Material Properties

Increasing the ABS sheet thickness enhances certain mechanical properties while decreasing others:

Strength

Thicker ABS sheets exhibit higher ultimate tensile and flexural strength. There is an almost linear relationship between sheet thickness and strength due to the higher cross-sectional area.

Rigidity

Thicker ABS offers greater rigidity and resistance to bending forces. This improves performance for load-bearing applications.

Weight

The thicker the ABS sheet, the heavier it will be per unit area. This needs to be considered based on any weight restrictions.

Thermal Resistance

Thinner ABS sheets have lower thermal resistance. They allow faster heat transfer compared to thicker sheets.

Formability & Pliability

Thinner 1-2mm ABS can be curved, bent and formed more easily versus 5-10mm sheets which hold their shape firmly.

Key Consideration Factors When Selecting ABS Sheet Thickness

Now that we’ve covered the major applications and material properties, let’s summarize the key factors to consider when determining the ideal ABS sheet thickness:

- Application - Match the thickness to the expected use and operating conditions. Will the ABS part need to withstand impacts, weathering, heat?

- Strength Requirements - Thicker ABS provides greater tensile and flexural strength. Factor in any strength needs.

- Weight Restrictions - Evaluate if the part has any weight limits, as thicker ABS will increase weight.

- Machining Methods - Thinner 1-2mm ABS for laser cutting, 3-5mm sheets for CNC routing.

- Dimensional Stability - Thinner ABS can warp easier during machining. Thicker sheets hold form.

- Budget - Thicker ABS costs more per sheet, factor this into quantities needed.

- Availability - Confirm the thickness you need is available from suppliers.

Quick Guide to Recommended ABS Sheet Thicknesses

Here is a quick table matching some common ABS sheet thicknesses with their best-suited applications:

| ABS Sheet Thickness | Appropriate Uses |

|---|---|

| 1-2mm | Laser cutting, model making, light displays |

| 2-3mm | Machining simple prototypes, hobby projects |

| 3-5mm | CNC routing, furniture parts, cabinetry |

| 5-10mm | Outdoor signs, structural components |

Conclusion

Determining the optimal ABS sheet thickness requires balancing the key factors of application, strength needs, weight limits, machining methods, and budget. While thinner 1-2mm sheets provide flexibility and low weight, thicker 3-5mm+ sheets offer enhanced durability and performance. Matching the thickness to the expected usage and properties needed is critical.

We hope this guide gives you a solid understanding of choosing the right ABS sheet thickness for your specific application. Check out our ABS sheets available in a range of sizes and thicknesses perfect for your next project.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 ABS plastic