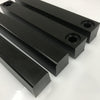

If you are looking for a plastic material that can meet your various needs and requirements, you may want to consider High Density Polyethylene. High Density Polyethylene, or HDPE for short, is a type of polyethylene that is made from the polymerization of ethylene. HDPE has high strength, high rigidity, high heat resistance, high chemical resistance, and high UV resistance. HDPE is widely used in various industries and applications, such as packaging, construction, automotive, medical, and more. In this blog post, we will introduce you to some of the main features and benefits of HDPE, as well as some of the processing and molding methods that can create different shapes and sizes of products from HDPE. We will also discuss the environmental and sustainability aspects of HDPE, and how it can fit the needs and preferences of European and American users who care about the planet and society. Let’s get started!

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 HDPE plastic

Features and Benefits of HDPE

HDPE has several features and benefits that make it a versatile, durable, and eco-friendly plastic material, such as:

- It has a high strength-to-density ratio. HDPE has a density of about 0.95 g/cm3, which is higher than other grades of polyethylene, but still lower than many other polymers. This means that HDPE is lightweight but strong, and has excellent impact strength. HDPE can withstand temperatures up to 90°C, which makes it suitable for applications that require heat resistance. HDPE is also resistant to most chemicals, solvents, acids, and bases, which makes it suitable for applications that require chemical resistance. HDPE is also resistant to UV rays, which makes it suitable for outdoor applications that require weather resistance.

- It can be processed and molded by various methods. HDPE can be processed and molded by different methods that can create different shapes and sizes of products from HDPE, such as extrusion, injection molding, blow molding, thermoforming, etc. These methods have their own advantages and disadvantages depending on the desired product characteristics and specifications. Extrusion is a process that involves forcing molten plastic through a die to form a continuous shape. Injection molding is a process that involves injecting molten plastic into a mold cavity to form a discrete shape. Blow molding is a process that involves inflating a hollow plastic tube inside a mold cavity to form a hollow shape. Thermoforming is a process that involves heating a plastic sheet and forming it over a mold or vacuum to form a shape.

- It is recyclable and reusable. HDPE is an eco-friendly and sustainable plastic material because it can be recycled and reused without losing its quality or properties. HDPE can be melted down and reprocessed into new products without generating much waste or pollution. HDPE can also replace some heavier or more harmful materials in some applications, such as metal or wood in some construction or packaging applications. This can reduce the energy consumption and carbon emission associated with producing and transporting these materials.

How to Choose HDPE for Your Plastic Products

If you are interested in choosing HDPE for your plastic products, you need to consider some factors, such as:

- The type of HDPE. There are different types of HDPE with different properties and characteristics, such as density, melt flow index, molecular weight distribution, etc. You need to choose the type of HDPE that suits your product specifications and requirements.

- The processing method. There are different processing methods that can create different shapes and sizes of products from HDPE, such as extrusion, injection molding, blow molding, thermoforming, etc. You need to choose the processing method that suits your product design and functionality.

- The supplier. There are different suppliers that can provide you with high-quality HDPE at competitive prices and fast delivery times. You need to choose a supplier that has rich experience and expertise in plastic processing and molding, such as www.beeplastic.com.

Conclusion

HDPE is a versatile, durable, and eco-friendly plastic material that can meet various needs and requirements in different industries and applications. It has excellent physical and chemical properties that make it adaptable to different environments and demands. It can be processed and molded by different methods that create different shapes and sizes of products from HDPE. It also has environmental and sustainability aspects that make it fit the needs and preferences of European and American users who care about the planet and society.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 HDPE plastic

If you want to learn more about HDPE or order some customized products from us, please visit our website www.beeplastic.com or send us an email at beeplastic@beeplastic.com. We are a professional plastic customization service provider with rich experience and expertise in plastic processing and molding. We can offer you high-quality products at competitive prices and fast delivery times. We look forward to hearing from you soon!