Dive into the world of UHMW Plastic Sheet Cut To Size with our latest blog post, "From Concept to Creation: Transforming UHMW Sheets into Precision-Cut Accessories." This comprehensive guide is your go-to resource for understanding the ins and outs of utilizing UHMW plastic—a material renowned for its durability, wear resistance, and versatility—in the creation of custom accessories.

We kick off with an in-depth look at Understanding UHMW Plastic: Properties and Benefits for Accessory Manufacturing, where we explore why this material stands out in the realm of accessory production. Discover the unique characteristics of UHMW that make it indispensable for crafting items that demand high impact strength and chemical resistance.

Next, we delve into The Precision Cutting Process, shedding light on the cutting-edge technologies that shape UHMW sheets into your exact specifications. Learn about the precision tools and techniques, from CNC machining to laser cutting, that ensure your designs are brought to life with unmatched accuracy.

Our journey continues with Design Considerations for UHMW Accessories, offering a treasure trove of insights on transforming your initial sketches into tangible, high-quality products. This section emphasizes the importance of design optimization to leverage UHMW's full potential, ensuring your accessories are not only functional but also aesthetically pleasing.

In Cost-Effective Procurement Strategies for UHMW Plastic Sheets, we equip you with knowledge on how to navigate the procurement process smartly and efficiently. From selecting the right supplier to understanding bulk ordering benefits, this segment is designed to help you maximize quality while minimizing costs.

Lastly, our Case Studies segment brings theory into the real world, showcasing innovative applications of cut-to-size UHMW sheets in various industries. These success stories highlight the material's adaptability and efficiency, inspiring you to push the boundaries of what's possible in accessory design.

Whether you're a seasoned manufacturer or a curious newcomer, "From Concept to Creation: Transforming UHMW Sheets into Precision-Cut Accessories" offers valuable insights into every step of the process. Join us as we explore how UHMW plastic sheets can elevate your accessory designs from mere concepts to market-ready creations.

Understanding UHMW Plastic: Properties and Benefits for Accessory Manufacturing

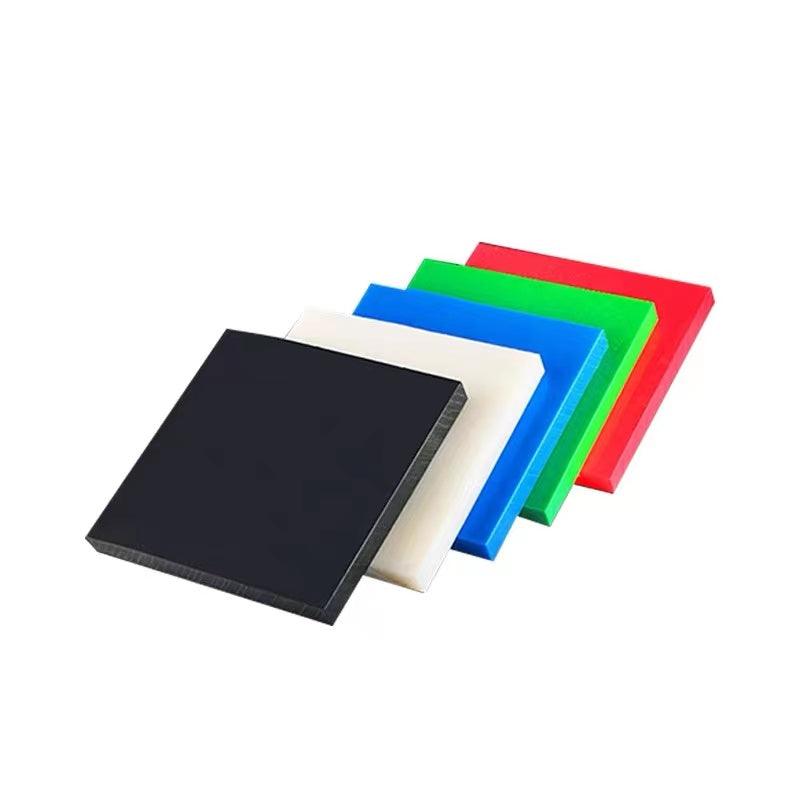

Ultra High Molecular Weight Polyethylene, or UHMW, stands as a cornerstone in the world of plastics, especially when it comes to crafting accessories that demand durability, resilience, and longevity. This material's unique set of properties not only sets it apart from other plastics but also makes it a preferred choice for a wide range of industrial and consumer applications.

The Unique Characteristics of UHMW

UHMW is renowned for its high impact strength, which enables it to withstand severe beating and abrasion without suffering damage. This characteristic is crucial for accessories that are exposed to harsh conditions, where regular plastics might crack or degrade. Whether it's gears, bearings, or any component that faces mechanical stress, UHMW's ability to absorb impact and resist wear extends the life of these products significantly.

Another notable feature of UHMW is its low friction coefficient. This quality not only reduces wear and tear on moving parts but also enhances performance by minimizing resistance. Accessories that require smooth, sliding actions benefit immensely from this property, ensuring efficient operation with less need for maintenance and lubrication.

UHMW also boasts exceptional chemical resistance. This makes it an ideal candidate for use in environments where exposure to corrosive substances is a concern. From industrial machinery parts to kitchen cutting boards, UHMW ensures that the integrity of the accessory remains uncompromised, even when in contact with aggressive chemicals.

Benefits for Accessory Manufacturing

The manufacturing of accessories with UHMW brings forth a plethora of benefits, directly attributable to its superior properties. The durability of UHMW translates into longer-lasting products, offering consumers better value for their investment and manufacturers a reputation for quality.

Moreover, the versatility of UHMW cannot be overstated. Its ease of fabrication and ability to be cut to size make it a go-to material for custom projects. Whether for industrial components or consumer products, UHMW can be tailored to meet specific requirements, offering unparalleled flexibility in design and application.

The cost-effectiveness of UHMW also plays a significant role in its popularity for accessory manufacturing. Despite its high-performance characteristics, UHMW remains an economically viable option, especially when considering its longevity and the reduction in maintenance costs it offers.

The Environmental Aspect

In today's eco-conscious world, the environmental impact of materials is more important than ever. UHMW is a non-toxic, recyclable plastic, which aligns with the growing demand for sustainable manufacturing practices. Its long service life and recyclability contribute positively to reducing waste and promoting a circular economy.

Final Thoughts

The unique properties of UHMW—from its high impact strength and low friction to its chemical resistance—make it an unparalleled choice for manufacturing durable, efficient, and versatile accessories. Its benefits extend beyond mere functionality, offering cost savings, design flexibility, and an environmentally friendly option for industries and consumers alike. As we continue to push the boundaries of innovation, UHMW stands as a testament to the role advanced materials play in shaping the future of manufacturing.