In the vast expanse of industrial manufacturing, materials such as PEI Plastic have carved a niche, offering unparalleled benefits and functionalities across a myriad of applications. The intrinsic properties of PEI Plastic not only stand out for their thermal stability but also for their mechanical strength and chemical resistance, making them a preferred choice in various sectors. This article aims to traverse through the realms of PEI Plastic Material, exploring its successful implementations and confronting the challenges encountered across diverse industries. Through a series of enlightening case studies, we shall delve into the practical applications, triumphs, and tribulations of utilizing PEI Plastic, providing a comprehensive view of its industrial impact.

Unraveling the Properties of PEI Plastic

Polyetherimide, commonly known as PEI Plastic, has emerged as a frontrunner in the world of high-performance plastics, owing to its exceptional PEI Plastic Properties that cater to the demanding needs of various industries. Characterized by its ability to retain its mechanical properties even at elevated temperatures, PEI Plastic has become synonymous with durability and reliability in harsh environments.

Thermal Stability: A Heat-Resistant Marvel

PEI Plastic is renowned for its impressive thermal stability, capable of maintaining its structural integrity under prolonged exposure to high temperatures. This attribute has propelled its use in industries such as aerospace and automotive, where materials are often subjected to extreme thermal conditions. But what exactly facilitates this remarkable heat resistance in PEI Plastic, and how does it compare to other materials in real-world applications?

Mechanical Strength: The Backbone of Industrial Applications

The mechanical prowess of PEI Plastic is not merely confined to its robustness but extends to its ability to withstand significant stress and strain without succumbing to deformation. This mechanical strength is not just pivotal in ensuring the longevity of the products but also in safeguarding their performance, especially in industries where the margin for error is minimal.

Chemical Resistance: Withstanding the Rigors of Industrial Environments

Navigating through the chemical landscapes of various industries, PEI Plastic demonstrates a commendable resistance to a wide array of chemicals. This resistance is not merely a barrier against corrosion but also a safeguard against potential compromises in material integrity when exposed to aggressive chemical environments.

The Pinnacle of Success - Case Studies on PEI Plastic Implementations

Embarking on a journey through the industrial applications of PEI Plastic, we shall explore a series of case studies that spotlight its successful implementations, the strategies employed, and the challenges encountered.

Case Study 1: Elevating Performance in the Electronics Industry with PEI Plastic

In the fast-paced world of the electronics industry, where miniaturization meets sophistication, materials like PEI Plastic have emerged as pivotal in ensuring durability, reliability, and enhanced performance of electronic components. The industry, characterized by its relentless pursuit of innovation and stringent quality standards, demands materials that can withstand high temperatures, resist various chemicals, and offer electrical insulation - all intrinsic properties of PEI Plastic.

Implementation Strategy: Bridging Innovation with Reliability

The strategy to implement PEI Plastic Material in the electronics industry was meticulously crafted, focusing on leveraging its unique properties to enhance the performance and longevity of electronic components. The inherent thermal stability of PEI Plastic was pivotal in developing components that could withstand the heat generated by electronic devices, ensuring reliability even in prolonged and intensive use. Moreover, its electrical insulation properties were crucial in preventing short circuits and ensuring the safe operation of electronic devices.

Challenges and Solutions: Navigating Through the Complexities

Despite the apparent benefits, the implementation of PEI Plastic in the electronics industry was not devoid of challenges. Ensuring consistent quality and performance of the PEI Plastic across various components, adhering to the industry’s stringent regulatory compliances, and scaling production to meet the growing demands of the industry were among the significant hurdles encountered. Solutions such as the development of standardized testing protocols for the PEI Plastic Material, establishing robust quality control mechanisms, and optimizing production processes were instrumental in navigating through these challenges, ensuring the successful incorporation of PEI Plastic in various electronic applications.

Outcomes: A Leap Towards Enhanced Electronic Components

The incorporation of PEI Plastic in the electronics industry marked a significant advancement in the development of robust and reliable electronic components. From enhancing the heat resistance of connectors to ensuring the electrical insulation of switches, PEI Plastic has facilitated the development of components that not only meet the demanding requirements of the industry but also pave the way for innovations in electronic devices.

Case Study 2: Revolutionizing the Medical Industry with PEI Plastic

The medical industry, with its stringent standards and relentless pursuit of innovation, has always been on the lookout for materials that can elevate the quality and safety of medical devices and equipment. PEI Plastic, with its remarkable PEI Plastic Properties, became a material of choice for several applications within this sector. The inherent biocompatibility, thermal stability, and chemical resistance of PEI Plastic have facilitated the development of medical devices that are not only safe but also highly efficient and durable. However, the journey of integrating PEI Plastic into the medical industry was punctuated with challenges such as adhering to regulatory compliances, ensuring absolute biocompatibility, and navigating through the complexities of medical device manufacturing.

Implementation Strategy

The strategy to implement PEI Plastic Material in the medical industry was multifaceted, focusing on leveraging its unique properties to enhance device performance while ensuring adherence to the stringent regulatory and quality standards prevalent in the sector.

Challenges and Solutions

Despite the apparent benefits, the implementation of PEI Plastic was met with challenges such as [specific challenges]. Innovative solutions and meticulous planning were instrumental in navigating through these hurdles, ensuring the successful incorporation of PEI Plastic in various medical applications.

Case Study 3: PEI Plastic in the Aerospace Industry

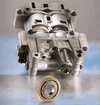

The aerospace industry, characterized by its extreme operating conditions and rigorous material demands, presented a unique challenge and opportunity for the implementation of PEI Plastic. The material, known for its high strength-to-weight ratio and exceptional thermal stability, became a pivotal component in the manufacturing of various aerospace components.

Sky-High Demands Meet Grounded Solutions

The demands of the aerospace industry are nothing short of challenging, with materials required to perform optimally in extreme conditions. PEI Plastic, with its ability to withstand high temperatures and resist various chemicals, provided a solution that was not only viable but also significantly advantageous.

Navigating Through Turbulence

The challenges encountered in the aerospace industry, such as [specific challenges], were met with strategic planning and innovative solutions that ensured the successful and safe implementation of PEI Plastic in various aerospace applications.

Navigating Through Challenges: A Holistic View

While the case studies provide a glimpse into the practical challenges encountered in specific industries, it is pivotal to explore the overarching challenges and solutions associated with implementing PEI Plastic across various sectors.

Challenge 1: Ensuring Consistent Quality

Ensuring the consistent quality of PEI Plastic Material across various applications and industries is paramount. The challenge lies in maintaining the intrinsic properties of PEI Plastic while catering to the unique demands of each industry.

Challenge 2: Scalability of Production

The scalability of producing PEI Plastic to meet the demands of various industries, without compromising on quality and performance, presents a significant challenge, especially in sectors that require large-scale production.

Challenge 3: Environmental and Regulatory Compliance

Navigating through the environmental and regulatory compliances, especially in industries like medical and aerospace, where standards are stringent, is a challenge that requires meticulous planning and adherence to global standards.

PEI Plastic vs. PEEK Plastic in the Automotive Industry: A Comparative Analysis

Navigating through the automotive industry, where durability and innovation drive success, materials like PEI Plastic and PEEK Plastic have found a prominent place, each offering a unique set of properties and benefits that cater to the specific demands of automotive applications.

Driving Durability with PEEK Plastic

PEEK Plastic, renowned for its mechanical strength and thermal stability, has been a game-changer in the automotive industry, contributing to the development of components that not only enhance the performance of vehicles but also ensure longevity and reliability. From lightweight components that enhance fuel efficiency to durable parts that withstand extreme conditions, PEEK Plastic has paved the way for innovations that align with the evolving demands of the automotive sector.

The Robustness of PEI Plastic in Automotive Applications

PEI Plastic, on the other hand, brings forth its own set of advantages to the automotive industry. With its exceptional thermal stability and resistance to automotive fluids, PEI Plastic has emerged as a material of choice for under-the-hood applications, providing solutions that are not only durable but also cost-effective.

Comparative Insights: PEI vs. PEEK

While both PEI Plastic and PEEK Plastic offer a range of benefits in automotive applications, the choice between the two often boils down to specific application requirements, cost considerations, and material availability. This section will delve into a detailed comparison, providing insights that can guide material selection in automotive manufacturing.

Future Prospects of PEI Plastic in Industrial Applications

As we traverse through the industrial landscape, exploring the various applications and challenges of PEI Plastic, it is pivotal to cast a glance towards the future, understanding the potential advancements and applications that lie on the horizon.

Advancements in Material Science

The future of PEI Plastic in industrial applications is closely tied to advancements in material science, exploring new formulations and processing techniques that can enhance its properties and expand its applicability across various sectors.

Sustainability and Environmental Impact

With a growing emphasis on sustainability, the development of PEI Plastic variants that are more environmentally friendly and compliant with global sustainability standards will be pivotal in ensuring its continued relevance and applicability in various industries.

Expanding Horizons: New Industries and Applications

Exploring new industries and applications for PEI Plastic, especially in emerging sectors like renewable energy and electric vehicles, will be crucial in expanding its industrial footprint and contributing to advancements in various fields.

The journey of PEI Plastic across various industries, marked by its successful implementations and the challenges encountered, provides a comprehensive view of its industrial impact and potential. From enhancing the performance of automotive components to ensuring the reliability of medical devices, PEI Plastic has showcased its versatility and robustness in numerous applications. As we look towards the future, the continuous exploration and advancement of PEI Plastic will pave the way for new applications, ensuring its sustained relevance in the ever-evolving industrial landscape.

Engage with Us

We invite you to share your thoughts, experiences, and insights on PEI Plastic and its applications across various industries. Your input is valuable in enhancing our understanding and exploring new horizons in the world of high-performance plastics.