Looking to master the technique of acrylic bending without cracking or damaging your material? This post covers everything from heat bending acrylic sheets to cold bending acrylic, ensuring you achieve clean, precise results. Whether you're using an acrylic sheet bender or a strip heater, this guide will walk you through the tools and techniques needed for safe and effective acrylic fabrication. Learn how to avoid mistakes like overheating and improper bending angles by following our tips on temperature control and the use of acrylic shaping tools. We'll also cover how to bend acrylic at home using DIY methods, as well as more advanced techniques like V-groove bending. Whether you're working on custom acrylic bending projects or handling plexiglass bending, this guide ensures you can shape bending plastic sheets with confidence.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 Acrylic plastic

Blog Post Summary:

-

The Science Behind Acrylic Bending – Explore the molecular process of acrylic softening under heat and how it allows you to bend without breaking.

-

Essential Tools for Precision Bending – Learn about acrylic sheet bending tools, from strip heaters to plastic bending machines, ensuring you have the right equipment.

-

Heat Bending vs. Cold Bending Techniques – Compare the advantages of heat bending and cold bending, and find out which method suits your project best.

-

Tips for Bending Acrylic Without Breaking – Step-by-step advice on avoiding common bending errors, including temperature control and correct tool usage.

-

DIY Acrylic Bending Guide – A detailed, practical guide for beginners on how to bend acrylic at home, using affordable tools and techniques.

-

Case Studies on Custom Acrylic Bending – Real-life examples of successful custom acrylic bending projects, showcasing the versatility and precision of bent acrylic parts.

Understanding Acrylic as a Thermoplastic Material

Acrylic, also referred to as Plexiglass, is a versatile material widely used in both industrial and DIY applications. What makes acrylic stand out is its nature as a thermoplastic, meaning it can soften and become malleable when exposed to heat, and harden again when cooled. This property allows it to be bent, shaped, and molded into various forms, making it ideal for acrylic bending projects ranging from retail displays to custom furniture.

Unlike thermosetting plastics, which can only be molded once, acrylic can be reshaped multiple times without losing its strength. This flexibility makes it a favorite for both heat bending acrylic sheets and cold bending applications. Whether you’re working on a DIY acrylic bending project or a large-scale custom job, understanding how to work with acrylic is crucial to achieving the best results.

How Heat Affects Acrylic at the Molecular Level

At the molecular level, acrylic is made up of long chains of polymers. When heat is applied, these chains loosen and become more flexible, allowing the acrylic to bend without breaking. The magic happens between 140°C to 160°C, which is the optimal range for bending acrylic. At this point, the material softens just enough to be molded or shaped without damaging its structure.

The key to precision acrylic bending is controlling this process carefully. If the material is overheated, it can start to form bubbles or warp, and in extreme cases, it can crack. On the other hand, if you don’t heat it enough, the material will remain too stiff, and any attempt to bend it will result in fractures. This is why using the right tools and maintaining proper temperature control is essential.

The Importance of Temperature Control in Acrylic Bending

Temperature control plays a vital role in the success of any acrylic bending project. Acrylic’s reaction to heat is highly sensitive, which means that even small deviations in temperature can significantly impact the outcome. For example, applying too much heat too quickly can cause the surface of the acrylic to discolor, bubble, or even start melting unevenly.

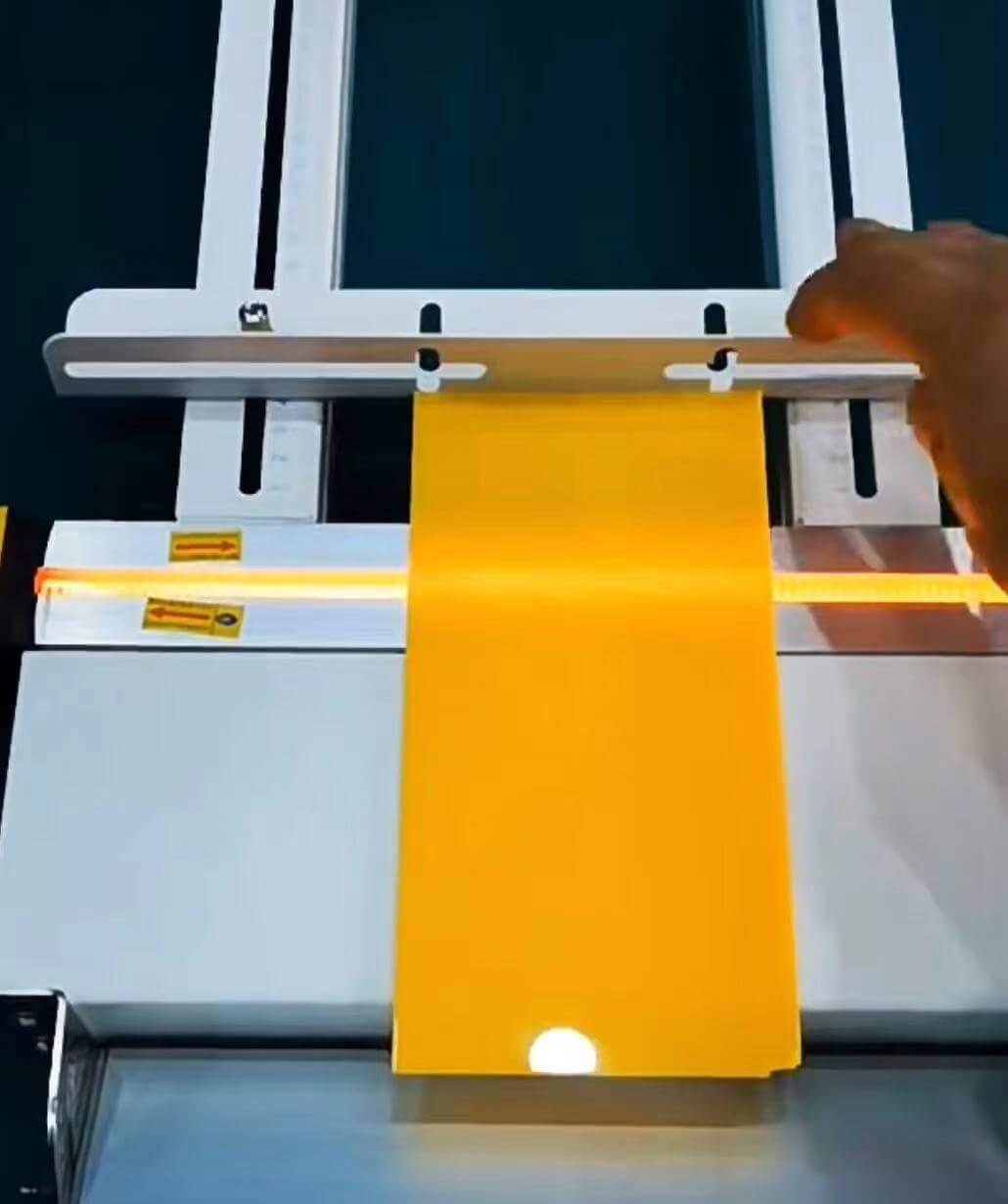

Using specialized tools such as strip heaters for acrylic ensures that the heat is distributed evenly across the bending line. This is especially important for projects requiring precise angles and curves, such as plexiglass bending for architectural installations or product displays. Acrylic sheet bending tools like these are designed to maintain consistent temperatures, ensuring that the acrylic softens gradually and bends smoothly without any risk of breaking.

Choosing the Right Tools for Acrylic Bending

Selecting the right tools is just as important as mastering the heating technique. Acrylic shaping tools, such as strip heaters and acrylic sheet benders, allow for controlled heating, which is crucial for projects requiring precision. These tools ensure that heat is applied only where needed, preventing the rest of the material from being affected. For DIY enthusiasts, using a heat gun or plastic bending machine can achieve good results, though it's important to practice with smaller pieces before moving on to larger projects.

Another essential tool for achieving smooth bends is a jig or a mold. A jig holds the acrylic in place while it cools, ensuring that the final shape is maintained. For complex shapes, like those needed in custom acrylic bending projects, a pre-designed mold can be used to guide the acrylic into intricate designs.

Best Practices for Successful Acrylic Bending Projects

Whether you're working on a simple DIY project or a more complex custom design, following best practices is critical to achieving clean and accurate bends. Always allow the material to reach its optimal temperature before attempting to bend it. Using strip heaters or other heat bending tools will give you more control over the heating process.

After the acrylic has softened and been bent to the desired angle, it's important to let it cool completely before removing it from the jig or mold. This cooling period is essential for ensuring that the material holds its new shape without warping or springing back. Patience is key—rushing this step can undo all the hard work put into achieving that perfect bend.

When working on larger projects or more intricate bends, it’s always a good idea to run a test on smaller pieces of acrylic first. This will give you a feel for how the material reacts to the heat and allow you to fine-tune the process before tackling the main project.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 Acrylic plastic