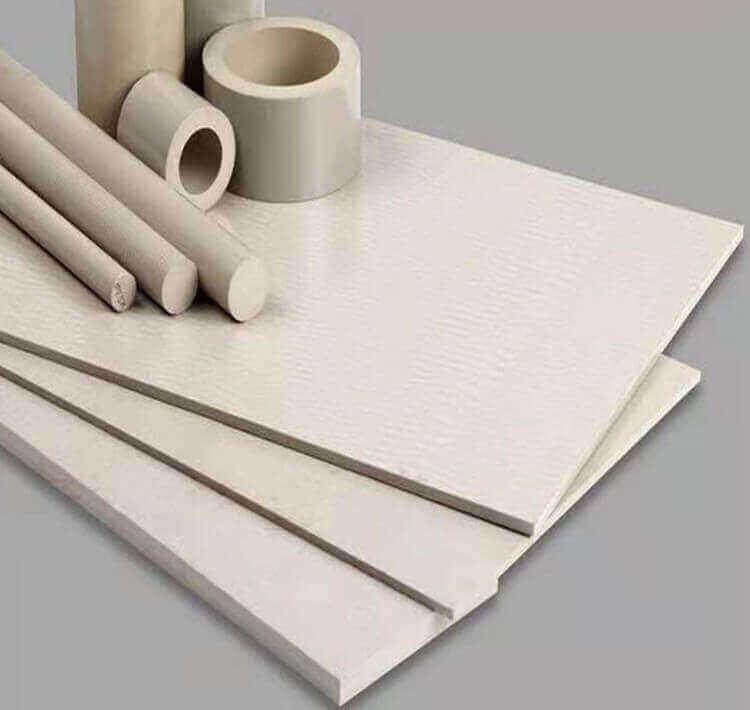

Imagine a plastic material that can handle anything you throw at it. A material that can resist high temperatures, harsh chemicals, and heavy wear. A material that can outperform other plastics and metals in many ways. Sounds too good to be true, right? Well, it’s not. It’s PEEK. PEEK is a high-performance thermoplastic that has a lot of benefits for engineering applications. In this blog post, we will show you what PEEK is, how it is made, what it can do, and where you can find it.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 PEEK plastic

What is PEEK and what makes it special?

PEEK stands for polyether ether ketone, which is a fancy name for a type of plastic. PEEK belongs to a family of plastics called polyaryletherketones (PAEKs), which are known for their amazing thermal and mechanical properties. PEEK was first developed in 1978 and introduced to the market in the early 1980s by two British companies: Victrex PLC and Imperial Chemical Industries (ICI).

PEEK is a semi-crystalline thermoplastic, which means that it has some order and some disorder in its molecular structure. The amount of order depends on how PEEK is processed and can affect how strong and stiff it is. PEEK has a high melting point of 343 °C (649 °F) and a glass transition temperature of 143 °C (289 °F), which means that it can keep its shape and function at high temperatures. PEEK also has a high tensile strength of 90 to 100 MPa (13,000 to 14,500 psi) and a Young’s modulus of 3.6 GPa (520,000 psi), which means that it can resist stretching and breaking under stress.

PEEK is not only strong and stiff, but also resistant to many types of damage. PEEK can resist wear, abrasion, fatigue, and creep, which means that it can last longer and perform better over time and under repeated loading. PEEK can also resist chemicals, solvents, acids, bases, and hydrolysis, which means that it can survive in corrosive environments. PEEK is also resistant to thermal degradation, UV radiation, gamma rays, and biodegradation, which means that it can withstand extreme conditions without losing its properties.

What are the different types of PEEK and how are they different?

PEEK comes in different types depending on how pure and reinforced it is. The most common type is PEEK 450G, which is an unfilled type with high purity and excellent mechanical properties. However, PEEK can also be reinforced with various fillers to improve its properties for specific applications. Some of the common fillers are:

- Carbon fiber: Carbon fiber makes PEEK stronger, stiffer, more thermally conductive, and more wear resistant, while making it lighter and less thermally expansive. Carbon fiber reinforced PEEK is good for applications that need high load-bearing capacity and dimensional stability at high temperatures.

- Glass fiber: Glass fiber makes PEEK stronger, stiffer, more heat resistant, and more dimensionally stable, while making it cheaper and lighter. Glass fiber reinforced PEEK is good for applications that need high rigidity and resistance to deformation at elevated temperatures.

- Other plastics: Other plastics such as polytetrafluoroethylene (PTFE), polyphenylene sulfide (PPS), or polyetherimide (PEI) can be mixed with PEEK to make it more slippery, more wear resistant, more chemical resistant, or more electrically insulating. These mixes are good for applications that need low friction or high insulation.

What are some of the unique benefits of PEEK that make it versatile?

PEEK has some unique benefits that make it stand out from other plastics and metals. Some of these benefits are:

- Biocompatibility: PEEK is biocompatible, which means that it does not harm living tissues or fluids when in contact with them. PEEK is also bioinert, which means that it does not degrade or interact with biological substances. These benefits make PEEK ideal for medical implants and surgical devices that need to be compatible with the human body.

- UV resistance: PEEK is UV resistant, which means that it does not degrade or change color when exposed to sunlight or artificial light sources. This benefit makes PEEK suitable for outdoor applications that need to resist weathering and aging.

- Radiolucency: PEEK is radiolucent, which means that it does not block or absorb X-rays or other forms of radiation. This benefit makes PEEK suitable for applications that need to be transparent to imaging techniques such as X-ray, MRI, or CT scan.

- Gamma-ray resistance: PEEK is gamma-ray resistant, which means that it does not degrade or change its properties when exposed to high-energy radiation. This benefit makes PEEK suitable for applications that need to survive in radioactive environments such as nuclear power plants or medical sterilization.

- Low/no toxicity: PEEK is low or non-toxic, which means that it does not release harmful substances or gases when heated, burned, or processed. This benefit makes PEEK suitable for applications that need to be safe and environmentally friendly.

PEEK is a high-performance plastic that has many benefits over other plastics and metals. It has a unique combination of strength, stiffness, temperature resistance, chemical resistance, wear resistance, and creep resistance. It also has some unique benefits such as biocompatibility, UV resistance, radiolucency, gamma-ray resistance, and low/no toxicity. These benefits make PEEK suitable for various engineering applications in aerospace, automotive, structural, high temperature electrical, and biomedical industries.

If you want to learn more about PEEK or use it for your next project, please contact us today. We can provide you with high-quality PEEK products and services at competitive prices. We can also help you with design, prototyping, testing, and manufacturing of your PEEK parts. We are looking forward to hearing from you soon.

🎉🎉🎉Limited Time Offer Use code: QR4GNY08SHVR at checkout and enjoy a special discount on your entire order! 👉 PEEK plastic